With the rapid development of knowledge economic and information technology age, the development of 3D mold promotes the development of related industries. Also, it speeds up the development of medical mold parts.

It’s known that the Stratasys Company, 3D printing and adding manufacturing equipment manufacturers, will cooperate with Worrell Design Company, the product design and product developers in the United States, through 3D printing plastic injection mold to speed up the development process of medical mold parts. Worrell Company currently use 3D printing mold to produce injection prototype parts. Compared with the traditional aluminum mold, it can save 95% of the time and save 70% of the cost.

In the aspect of medical apparatus and instruments coming to market, medical device manufacturers have always been faced with two big obstacles: the mold cost and the the regulatory process of United States food and drug administration. Kai Worrell, the CEO of Worrell Company said, “ Recently, the initial medical device company ask us design and engineering manufacture a double needle blood system, in order to reduce the need for multiple doses and improve patients’ comfort and efficiency of the hospital.”

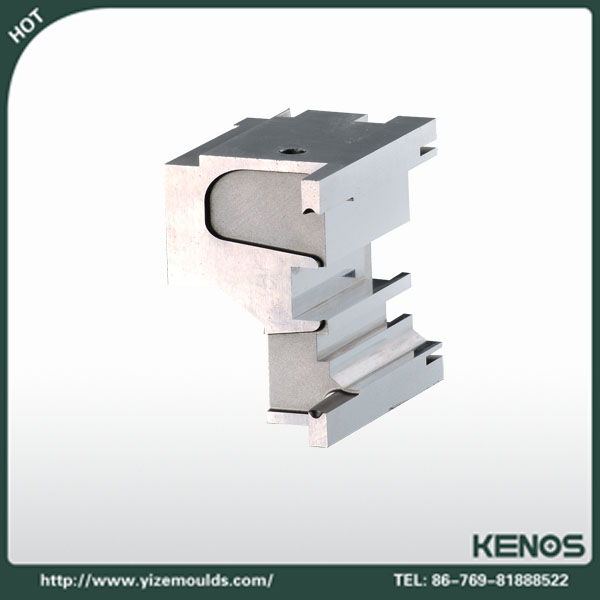

The development of medical mold parts will also accelerate the development of medical instrument accessories industry. So there are development on the one hand, related industry also will follow the progress. Dongguan Yize Mould is a professional precision connector mold parts manufacture. We specialized in precision mold parts for many years and have many years of industry experience. It is our pleasure to help you deal with your difficulties in mold parts.