As we all know, regular maintenance of the mould can keep its best performance state and prolong its service life, so as to ensure the normal production. Do you pay attention to mold maintenance? Let's take a look at how to maintain the mold:

First of all, each mold should be equipped with inspection and maintenance table to record and count its use, care and damage, and then judge which parts and components have been damaged and the degree of wear, so as to provide information for finding and solving problems.

Secondly, under the normal operation of the injection molding machine and the mold, test the various properties of the mold, and measure the size of the final molded plastic parts. Through these information, we can determine the existing status of the mold, find out the damage of the cavity, core, cooling system and parting surface. According to the information provided by the plastic parts, we can judge the damage status of the mold and the maintenance measures.

At the same time, several important parts of the mold should be tracked and tested: the ejecting and guiding parts are used to ensure the opening and closing movement of the mold and the ejecting of the plastic parts. If any part is stuck due to damage, it will lead to production suspension. Therefore, the lubrication of the die thimble and guide pillar should be kept regularly (the most suitable lubricant should be selected), and the deformation and surface of the thimble and guide pillar should be checked regularly Once the damage is found, it shall be replaced in time; after a production cycle, the working surface, moving and guiding parts of the mould shall be coated with professional antirust oil, especially the protection of the elastic strength of the bearing part of the mould with gear and rack and the spring mould shall be paid attention to, so as to ensure that it is always in the best working condition; With the continuous production time, the cooling channel is easy to deposit scale, rust, sludge and algae, which makes the cross section of the cooling channel smaller and the cooling channel narrower, greatly reduces the heat exchange rate between the coolant and the mold, and increases the production cost of the enterprise. Therefore, attention should be paid to the cleaning of the channel; For hot runner mould, the maintenance of heating and control system is helpful to prevent production failure, so it is particularly important. Therefore, after the end of each production cycle, the belt heater, rod heater, heating probe and thermocouple on the mold shall be measured with ohmmeter. If they are damaged, they shall be replaced in time, compared with the mold resume, and records shall be made so that problems can be found in time and countermeasures can be taken.

In addition to the regular maintenance of the mold, the daily cleaning and maintenance can not be less, which can not only improve the service life of the mold, but also save the production cost and improve the production efficiency to a certain extent, so we must do a good job in daily maintenance and regular maintenance!

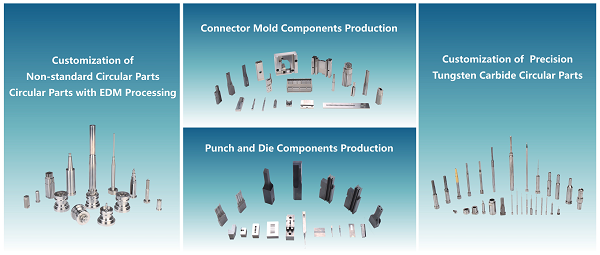

The above is the mold maintenance method summarized by Yize mould for you. You can contact us to purchase mechanical mold parts, plastic mold components, stamping mold parts and other precision mold parts, and we will wholeheartedly provide services for you~