Many customers in the purchase of stamping die parts, will require its hardness and die consistent. Because the hardness of stamping die is not enough, the parts will be affected, the burr will exceed the standard, and the die life will be affected, thus increasing the punch load forming, and the forming die will affect the surface quality of parts.

The hardness of stamping die parts is directly proportional to wear resistance. Generally, the higher the hardness of stamping die parts, the smaller the wear amount and the better the wear resistance. At the same time, the wear resistance is also related to the type, quantity, shape, size and distribution of carbide in the material.

Stamping mold parts factory Yize remind you that the following characteristics should be considered when purchasing stamping die parts:

1. toughness

The working conditions of the dies are very bad, and they often bear large impact load, which leads to brittle fracture. In order to prevent this situation, the die parts should have high strength and toughness, which mainly depends on the carbon content, grain size and microstructure of the material.

2. wear resistance

As mentioned before, the wear resistance of stamping die parts is one of the most basic and important properties of the die. Because the billet flows and slides along the surface of the mold cavity when it is plastic in the mold cavity, which causes severe friction between the surface of the mold cavity and the billet, resulting in the failure of the mold due to wear.

3. Fatigue fracture resistance

In the working process of stamping die parts, under the long-term action of cyclic stress, it often leads to fatigue fracture. Its forms are small energy multiple impact fatigue fracture, tensile fatigue fracture contact fatigue fracture and bending fatigue fracture.

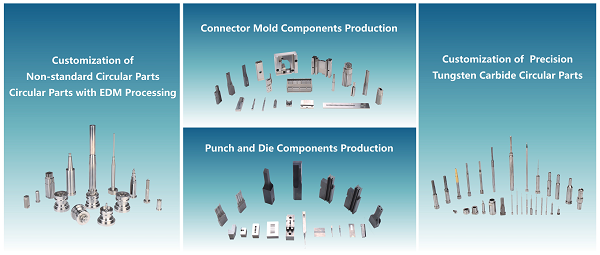

Yize mould, which has more than ten years of experience in stamping mould parts processing, is reliable. It provides you with a series of products, such as precision mould parts, precision plastic mould parts, hardware stamping mould parts, connector mould parts, non-standard round parts, tungsten steel parts, etc. welcome to consult us~