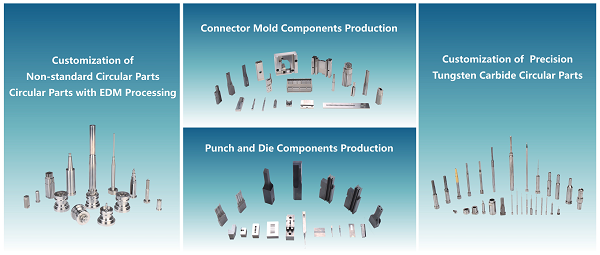

Dongguan Yize mould provides non-standard custom services for all kinds of metal stamping dies - non-standard custom punch and die components.

Stamping die is the basic equipment of industrial production. 60% - 80% of the parts in the electronic automobile, electrical machinery, instruments, meters, home appliances and communication products need to be molded by die.

Stamping die is a kind of special process equipment which processes materials (metal or non-metal) into parts (or semi-finished products) in cold stamping process. It is called cold stamping die (commonly known as cold stamping die). Stamping is a kind of pressure method which uses the die installed on the press to exert pressure on the material to make it produce separation or plastic deformation, so as to obtain the required parts.

Dongguan precision die parts factory Yize provides precision punch and die parts, non-standard custom punch and die components. Yize, founded on January 1, 2007, is located on the 3rd floor, No. 62, Jinghai East Road, Shatou community, Chang'an Town, Dongguan City, Guangdong Province, China, with a factory area of 4500 square meters. At present, the company has 125 employees, including 96 direct production personnel. Is a professional production of precision mold parts processing and manufacturing enterprises.

Each customer needs different stamping die parts. Therefore, Yize can non-standard custom punch and die components according to customer drawings. We have high skilled personnel, advanced production technology, high-level automation equipment and professional Japanese technical consultants. If you need to contact us, please contact us directly. The price is more favorable~