How to do a good job of connector mold parts machining requirements, let's take a look.

Precision connector mold parts machining is one of the most effective methods for enterprise's mechanical mold processing. Compared with traditional processing technology, it adopts the procedure of reducing the number of loading and operating steps of the workpiece. In addition, it keeps the orientation and perfect process manufacturing.

In order to ensure the precision of die processing, improve the quality of production and reduce production costs, connector mold parts machining has a strong oxidation, but also shows the following characteristics:

1.There is a certain lower deformation resistance and a certain range of temperature.

2.High and balanced surface strength after quenching.

3.The quality requirement of grinding wheel and the unstable cooling environment are not easy to cause damage and cracks.

4.The cutting quantity is large, the wear degree is low, and the roughness of the surface is low.

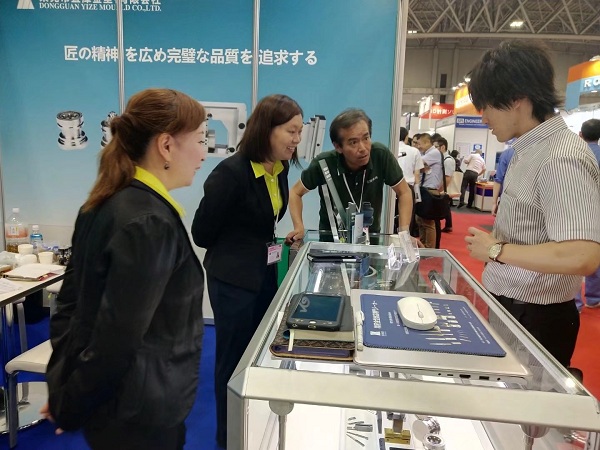

YIZE MOULD is a manufacturer of connector mold parts machining in Dongguan. We can provide you with professional hardware connector mold parts manufacturing services. If necessary, please contact us,our company will reply to you as soon as possible!