In the manufacturing process, Manufacture of plastic mold parts challenges industry faces a variety of quality, cost, and cycle challenges.

1. There is price competition in the Manufacture of plastic mold parts challenges.

There is fierce competition between middle-end and low-end molds. The entire industry is epidemic-affected to compete for market share, with too much and too little money. Many manufacturers report that profits are not worth the cost and are willing to do business at a loss, even if they are processed. The labor cost of the process exceeds the cost, and fierce competition in the industry intensifies. Faced with payment defaults, SMEs are at risk and can be fatally hit.

2. One of the Manufacture of plastic mold parts challenges that if unable to update and upgrade manufacturing equipment in time, the production cycle will be affected.

There are several leading mold companies in the area, but some self-employed or private companies are understood to be limited by many factors such as funding, location, technology and information exchange. It is difficult to introduce advanced mold making technology and advanced mold making equipment. Centralized production of some medium and low end molds, even at low prices, intensifies internal competition in the medium and low end mold market and exacerbates the internal consumption of local industrial resources. Many colleagues are reselling the original machine tools to offset their accounts.

3. One of the Manufacture of plastic mold parts challenges that If the company not improve the accuracy of the product in time, the quality of the product will be affected.

Due to the unique characteristics of the mold industry, especially the enormous cost, personnel, and time that a single product occupies, the quality of the product has a significant impact on the company's performance. On the other hand, as the basic equipment of the downstream processing and manufacturing industry, the accuracy, accuracy, stability and intelligence of the mold also determine the quality level of the back-end product and affect the quality control and management efficiency. Mold processing and manufacturing company. And the other side advocates higher requirements.

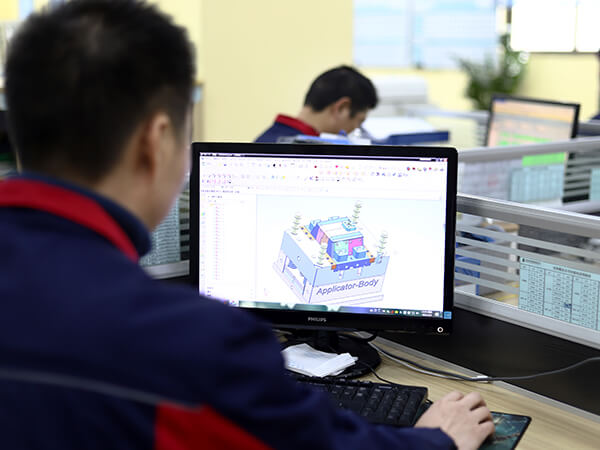

4. From manual manufacturing to digital manufacturing-ERP

Yize Mold, precision mold parts manufacture has adopted ERP to shift processing to digital manufacturing. The operator uploads the manufacturing process to the ERP. As long as senior managers and sales reps have the computer turned on, they will be able to see the operation of all the equipment in the workshop and help improve the connector type. With the precise manufacturing capacity of spare parts, we can trace the origin, find the corresponding personnel for products and processed products, and realize the manufacturing mode on the Internet