Today, Yize mould shares with you a knowledge point that mould people must master -- precautions for selection of ejector pin of plastic mould.

Ejection system is one of the important functional structures of injection mold. It consists of a series of ejection parts and auxiliary parts, which can have different ejection actions. Ejector pin class is the most commonly used ejection method. Thimble type ejection components, including round ejector pin, shoulder ejector pin, core blade ejector pin, push tube. Precautions for selection of ejector pin of plastic mould are as follows:

1. Prevent the deformation or damage of the plastic part, correctly analyze the size and position of the adhesion of the plastic part to the mold cavity, and select the appropriate demoulding device to make the top force applied to the part with the largest rigidity and strength of the plastic part, that is, the top force should be on the wall as far as possible, under the bone position and column position, and the action area should be as large as possible (that is, the ejector pin with the largest diameter should be selected as far as possible) to prevent the deformation of the plastic part Or damaged.

2. The structure shall be reasonable and reliable, the ejector mechanism shall be reliable in operation, flexible in movement, convenient in manufacture, easy to replace and have sufficient strength and rigidity.

3. When the diameter of the ejector pin is below φ 2.5 and the position is enough, the shouldered thimble shall be made; when the push pipe wall is below 1mm or the push pipe wall diameter ratio is ≤ 0.1, the shouldered push pipe shall be made, and the fixed part shall be as large as possible. The effective matching length of thimble = (2.5-3) d, the minimum should not be less than 8mm, we generally take 20-25mm in the manufacturing process.

4. The ejector pin shall not be placed at the joint of the insert as far as possible

5. For the long arc glue position above 10 mm high, it is recommended to use flat thimble. The shorter the flat body is, the better the strength is, and the easier the processing is. The length of the cylindrical part shall be indicated in the design specification; for the pipe column with the height of more than 10 mm, it is recommended to push the pipe out.

6.In case of inclined thimble, in order to prevent the product from sliding with the inclined thimble, the "+" slot shall be ground on the thimble surface near the inclined thimble.

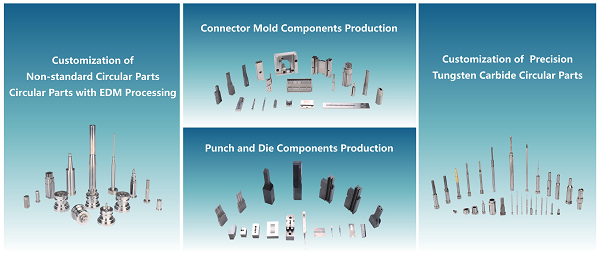

More knowledge about mold parts processing, please continue to pay attention to us. Yize mold provides you with precision plastic mold parts, connector mold parts, stamping mold parts, tungsten steel mold parts, precision mold round parts, mechanical mold parts and other precision mold parts. Welcome to contact us~