Design and manufacturing are complementary and inseparable. The manufacturing process is a bridge between design and manufacturing. Design is the first step in meeting customer needs before manufacturing. The same applies to precision mold components of design

precision mold components of design can primarily find the optimal balance between customer needs, market needs, and technical feasibility to satisfy and profit stakeholders. Is to do so. Customer demand is the original intent of every design and one of the key considerations for future product improvements.

At the same time, product manufacturing costs and competitive product differentiation have the potential to gain a place for market competition. The former two elements are based on a practical technical foundation and the direction of development of precision plastic mold parts processing.

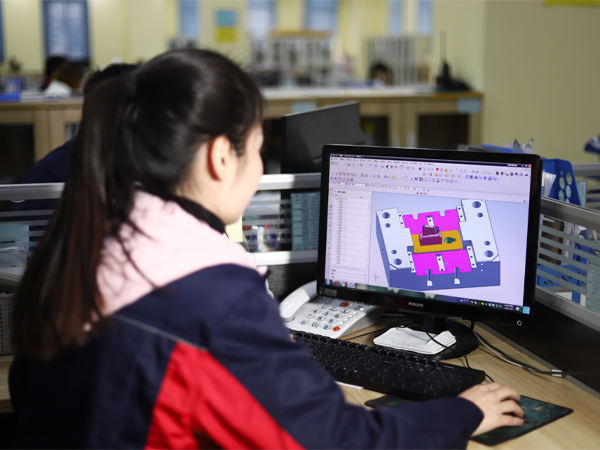

Manufacturing is the precision mold components of design. For over a decade, Yize Mold has been working on the introduction of highly skilled personnel, advanced production technology, and continuous improvement in the accuracy of automation equipment. With more than 100 operators today, CNC implementation enables the entire service process from mold design, manufacturing, and assembly to final mold trials.

Yize Mold has always wanted to be a reliable China mold components supplier of holistic solutions. Knowledge about mold making will be shared later and we will continue to pay attention to ourselves and get more surprises.