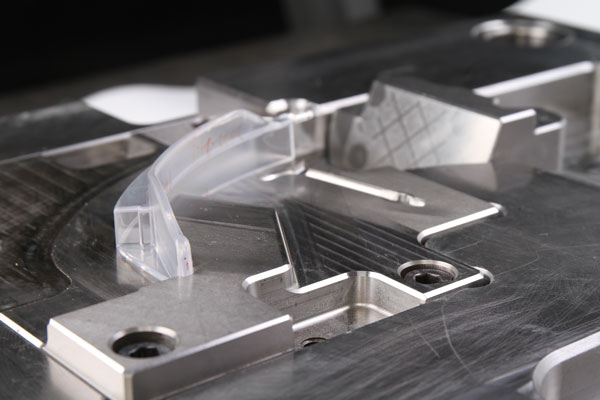

Many plastic products we see daily are produced in large quantities through plastic molds. Plastic molds have certain performance requirements for mold materials to adapt to various working conditions and environmental demands. What are the performance requirements for plastic mold materials?

High-Temperature Performance

When the working temperature of plastic molds is high, their hardness and strength decrease, leading to early wear, plastic deformation, and failure of the molds. Therefore, mold materials should possess high tempering resistance to ensure that plastic molds maintain high hardness and strength at working temperatures.

Resistance to Thermal Fatigue

Some plastic molds are repeatedly heated and cooled during operation, causing stress on the cavity surface due to tension and pressure. This leads to surface cracking and spalling, increased friction, hindered plastic deformation, and reduced dimensional accuracy, ultimately resulting in mold failure. Thermal fatigue is one of the main forms of failure for hot-work molds. Thus, they should have high resistance to both cold and thermal fatigue.

Corrosion Resistance

During the operation of plastic molds, the presence of elements like chlorine and fluorine in plastics generates highly corrosive gases after heat decomposition. These gases erode the cavity surface, increasing its surface roughness and accelerating wear.

Wear Resistance

When the billet undergoes plastic deformation in the mold cavity, it flows and slides along the cavity surface, generating severe friction between the cavity surface and the billet. This friction leads to mold failure due to wear. Therefore, wear resistance is one of the fundamental properties of plastic mold materials. Hardness is the main factor affecting wear resistance. Generally, the higher the hardness of mold components, the smaller the wear amount and the better the wear resistance. In addition, wear resistance is also related to the type, quantity, shape, size, and distribution of carbides in the material.

Toughness and Strength

Most molds’ working conditions are very harsh, and some are frequently subjected to large impact loads, leading to brittle fracture. To prevent sudden fracture of plastic mold components during operation, plastic molds must have high strength and toughness. The toughness of molds mainly depends on the carbon content, grain size, and microstructure of the material.

During the processing of plastic molds, fatigue fracture often occurs under the long-term action of cyclic stress. Its forms include low-energy multi-impact fatigue fracture, tensile fatigue fracture, contact fatigue fracture, and bending fatigue fracture. The fatigue fracture performance of molds mainly depends on their strength, toughness, hardness, and the amount of inclusions in the material.

Founded in 2007, Dongguan Yize Mould Co., Ltd. is a precision mold design, manufacturing, and precision injection molding products production enterprise with years of experience. The company focuses on providing a complete set of solutions integrating product design, precision mold manufacturing, injection molding, assembly, and after-sales service for automotive connectors, medical product injection molding, cleanroom injection molding, and PFA custom injection molding. Welcome to inquire at +86 13302615729 (same number for WeChat and WhatsApp).