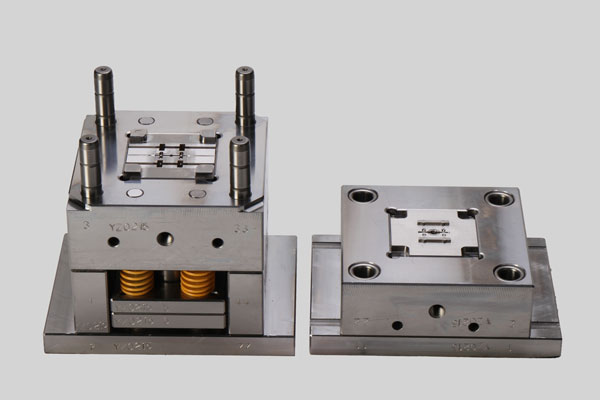

In the field of mold manufacturing, the three-plate mold plays a vital role in injection molding with its unique design and functionality. Below is a detailed introduction to the mold opening sequence of the three-plate mold, providing you with an in-depth understanding of the working process of this precision mold.

A three-plate mold is mainly composed of three parts: one is located between the runner plate and the cavity plate, another is between the runner plate and the top clamping plate, and the third is between the cavity plate and the core plate.

Initial Mold Opening Stage

When the core is subjected to the pulling force of the injection molding machine, due to the nylon lock between the core and the cavity plate, and the lack of direct connection or restraint between the runner plate and the cavity plate (in most cases, the small tie bars are also equipped with springs), under the pulling force, the runner plate will first separate from the cavity plate. Subsequently, the cavity plate will move backward together with the core plate until reaching a preset distance, which is blocked by the stoppers of the small tie bars. This stage is the initial action of mold opening, laying the foundation for subsequent operations such as demolding.

Further Movement of the Runner Plate

The cavity plate continues to move backward under the continuous pushing of the injection molding machine. This movement drives the small tie bars to move, which in turn causes the runner plate to move to a preset distance. During this process, the gate and runner are smoothly unloaded. After completing the preset distance of movement, the small tie bars and the cavity plate stop moving. This step ensures the separation of the gate and runner from the product, preparing for the subsequent ejection of the product.

Separation of the Cavity Plate and the Core Plate

The injection molding machine continues to move backward, increasing the pulling force. When the pulling force exceeds the clamping force of the nylon lock, the cavity plate and the core plate will separate by a preset distance before stopping. This separation action is a crucial link in the mold opening process of the three-plate mold, enabling the product to be smoothly detached from the core and creating conditions for the removal of the product.

Product Ejection

Under the pushing of the ejector of the molding machine, the ejector plate starts to drive the ejection system, which includes components such as ejectors, sleeves, and lifters. Under the action of the ejection system, the finished product begins to be ejected and can then be unloaded automatically or with the help of a robotic arm. This stage realizes the removal of the product from the mold and is a crucial step in the entire molding cycle, directly affecting the quality and production efficiency of the product.

Reset of the Ejector Plate

Under the pushing of the injection molding machine, the core starts to move towards the cavity. If the ejector plate is not pulled back in advance, the return pins will first contact the cavity plate. Under the reaction force, the ejector plate returns to its original position through the reset pins. This step ensures that the ejection system can reset after completing the ejection task, preparing for the next molding cycle and ensuring the mold’s normal operation and the product’s molding quality.

Mold Closing Preparation

Finally, the core plate is pressed against the cavity plate and the runner plate until the mold is tightly closed. At this time, the nozzle on the injection molding machine is in close contact with the nozzle bushing on the mold, making full preparations for the next molding cycle. This stage marks the end of the current molding cycle and also opens the prelude to a new molding cycle.

The above is the entire molding cycle of the three-plate mold. Each step is closely connected and interlinked, jointly ensuring the efficient and stable progress of the injection molding process. It is hoped that through this article, everyone can have a clearer and more in-depth understanding of the mold opening sequence of the three-plate mold.