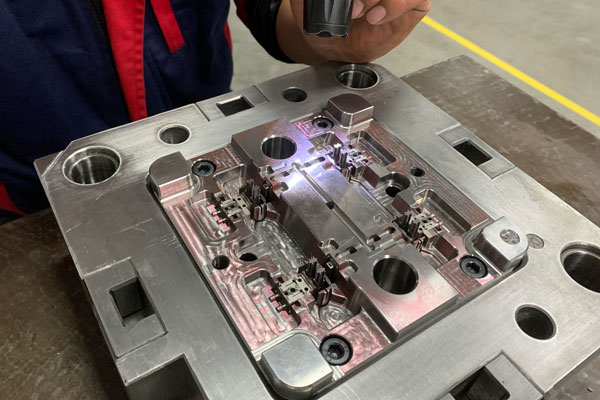

Among various mold types, automatic thread unscrewing molds have stood out due to their unique advantages and are widely recognized as the best option for manufacturing high-precision molds. They are mainly used in the production of various accessories.

Innovation Wave Driving Reform in the Mold Industry

In recent years, innovation has surged across all fields, and the mold industry is no exception. With the emergence of advanced tools and precision machines, mold manufacturing technology has made remarkable leaps forward. Nowadays, with the aid of these high-tech means, we can easily create molds of various shapes and sizes to meet the diverse needs of different industries and products. Whether it’s complex and precise molds for electronic components or large and heavy molds for automotive parts, they can all be realized with the support of advanced technology. This innovation has not only broadened the application scope of mold manufacturing but also provided a strong impetus for the development of the entire manufacturing industry.

Significant Advantages of Automatic Thread Unscrewing Molds

The reason why automatic thread unscrewing molds hold an important position in the field of mold manufacturing lies in their series of remarkable advantages, which play a crucial role in improving production efficiency, ensuring product quality, and reducing costs.

- Thin yet Sturdy Inner Walls: Thread-unscrewing molds can produce products with thin but extremely sturdy inner walls. This characteristic is of great importance in many application scenarios where both space and strength are strictly required. For example, in the aerospace industry, components need to be as lightweight as possible while maintaining high strength. The products manufactured by these molds precisely meet this requirement. Their thin yet sturdy inner wall structure can withstand high-intensity pressure and stress while effectively reducing the overall weight of the product, thereby improving the performance and fuel efficiency of the aircraft.

- Runner-Free Design for Reduced Waste: Compared with traditional mold manufacturing methods, automatic thread unscrewing molds adopt a runner-free design. In traditional molds, the runner is the channel through which materials such as plastics enter the mold cavity from the injection molding machine. This part of the material becomes waste after the injection molding process, resulting in resource waste. The runner-free design of automatic thread unscrewing molds allows the material to directly and accurately enter the cavity, avoiding the waste of material in the runner section. This greatly improves the material utilization rate, reduces production costs, and also conforms to the requirements of green manufacturing and sustainable development in today’s society.

- Faster Cycle Times: In the production process, time is money, and efficiency is life. Automatic thread unscrewing molds have faster cycle times, allowing for the production of more products within the same period. Their unique design and advanced thread unscrewing mechanism enable the products to be quickly and smoothly ejected from the mold after injection molding, reducing the waiting time of the mold and improving the overall operating efficiency of the production line. For large-scale production enterprises, faster cycle times can significantly shorten the production cycle, increase production capacity, and enhance market competitiveness.

- Higher Precision: Precision is a core indicator of mold manufacturing, directly affecting the quality and performance of products. Through precise design and advanced manufacturing processes, automatic thread unscrewing molds can achieve extremely high dimensional and shape accuracy. In industries such as electronics and medicine, where product precision requirements are extremely high, the components manufactured by these molds can meet strict tolerance requirements, ensuring the stability and reliability of the products. For example, in the medical field, the high-precision mold-manufactured medical device components can guarantee the accuracy and safety of surgeries, providing strong protection for patients’ health.

- Lower Mold Costs: Although the initial investment in automatic thread unscrewing molds may be relatively high, they can significantly reduce mold costs in the long run. On the one hand, their runner-free design and faster cycle times reduce material waste and production time, lowering production costs. On the other hand, due to their high precision and long service life, the frequency of mold maintenance and replacement is reduced, further lowering the operating costs of enterprises.

- Wide Material Adaptability: These kinds of molds have strong material adaptability and can mold almost any type of material. Whether it’s common plastics and rubbers or high-performance engineering plastics and composite materials, automatic thread unscrewing molds can be optimized according to the characteristics of different materials to achieve high-quality molding. This wide material adaptability enables automatic thread unscrewing molds to be widely used in various industries, meeting the diverse needs of different products for material performance.

- Rich Options for Colorants: In today’s world where product appearance is increasingly important, unscrewing molds also offer a wide range of colorant options. Enterprises can choose various colors and effects of colorants according to the product design requirements and market demands, giving the products a unique appearance. Whether it’s bright colors, soft tones, or special texture effects, automatic thread unscrewing molds can easily achieve them, making the products more attractive and competitive in the market.

Selecting High-Quality Services for Efficient Production

Choosing the right service provider of automatic thread unscrewing molds is crucial for enterprises to obtain high-quality products. Professional service providers not only have advanced equipment and technology but also possess rich experience and a professional team. They can provide customized solutions according to the specific needs of enterprises. In addition, high-quality services are also reflected in fast delivery times. In today’s fast-paced market environment, time is a business opportunity. Fast delivery enables enterprises to launch their products on the market more quickly and seize market share.

Automatic thread unscrewing molds, with their numerous significant advantages, have become a leader in the field of mold manufacturing. In the future, with the continuous progress and innovation of technology, these molds will undoubtedly play a greater role and bring more opportunities and possibilities to the development of the manufacturing industry. Enterprises should fully recognize the value of them and actively adopt this advanced technology to improve their production levels and market competitiveness.