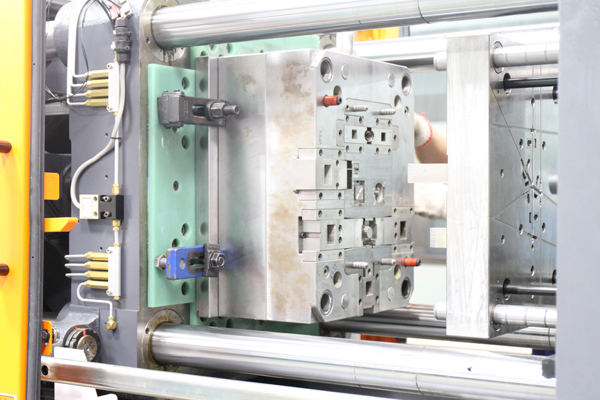

In the field of plastic mold injection molding, smoothly removing plastic parts from the mold cavity is a crucial step to ensure production efficiency and product quality. Usually, plastic parts rely on the ejection mechanism in the mold for demolding. However, when the product has a special shape, demolding difficulties may arise. So, what factors exactly lead to the inability of products to be smoothly demolded? Below, a detailed analysis will be conducted from three core aspects: plastic molds, injection molding processes, and raw materials.

I. Plastic Molds: “Hardware Hazards” in Demolding Dilemmas

Ejection Structure and Position: The “Fatal Flaw” of Design Defects

The ejection structure is a key design element for ensuring the smooth removal of plastic parts from the mold. Suppose the ejection structure is unreasonably designed, such as having an insufficient number of ejector pins, a scattered layout, or an ejection method that does not match the shape of the plastic part. In that case, it can result in uneven ejection force, causing the plastic part to get stuck during the demolding process. Additionally, if the ejection structure is improperly positioned, for example, if the ejector pins are placed in areas of the plastic part with weak strength, it will not only fail to eject the plastic part effectively but may also cause damage to it.

Draft Angle: The “Invisible Steps” for Smooth Demolding

The draft angle is an indispensable element in mold design, providing the necessary inclined angle for the demolding of plastic parts. If the draft angle is insufficient, the friction between the plastic part and the mold cavity increases, and the demolding resistance rises accordingly. This problem becomes more pronounced when the plastic part has a complex shape and deep side walls, making demolding even more difficult.

Mold Temperature and Ventilation: The “Double Test” of Temperature and Airflow

Excessive mold temperature can lead to insufficient cooling of the plastic part, resulting in uneven shrinkage and an increased adhesion force between the plastic part and the mold cavity, thereby increasing the difficulty of demolding. At the same time, poor mold ventilation is also a common issue. During the injection molding process, air remains trapped in the mold cavity. If it cannot be discharged promptly, it can form bubbles or burn marks inside the plastic part and also hinder the demolding process, even causing deformation of the plastic part.

Sprue and Cavity Surfaces: The “Invisible Resistance” of Rough Surfaces

Rough sprue walls or cavity surfaces are important factors affecting demolding. A rough surface increases the friction between the plastic part and the mold, making the demolding process more difficult. In addition, if the cavity surface is damaged or worn, it will not only affect the surface quality of the plastic part but also further increase the demolding resistance.

Main Runner Diameter and Nozzle Orifice Diameter: The “Size Trap” of Improper Matching

The matching between the diameter of the main runner and the diameter of the nozzle orifice is crucial. If the two diameters do not match, it can lead to excessive pressure loss or poor flow of the melt during the injection process, thereby affecting the filling and cooling effects of the plastic part and ultimately increasing the difficulty of demolding.

Gate Balance: The “Fair Path” for Melt Flow

Poor gate balance can result in inconsistent melt flow rates into the cavity. In some areas, the melt fills too quickly, which may generate internal stresses; while in areas with slow filling, the plastic part may not cool sufficiently, causing it to adhere tightly to the mold cavity and increasing the demolding resistance.

II. Molding Process: “Human-Induced Troubles” from Improper Operations

Injection Pressure: The “Power Dilemma” of Excessive Force

Injection pressure is a key parameter in the injection molding process. If the injection pressure is too high, the plastic part will be excessively squeezed in the mold cavity, resulting in a high degree of adhesion to the mold and thus increasing the demolding resistance. Moreover, excessive injection pressure can also lead to internal stresses inside the plastic part, affecting its dimensional stability and mechanical properties.

Mold Temperature: The “High-Temperature Trap” in Demolding Difficulties

Excessive mold temperature prolongs the cooling time of the plastic part and leads to insufficient cooling. When the plastic part is demolded before it is fully solidified, it is prone to deformation or damage. At the same time, high temperatures also increase the adhesion force between the plastic part and the mold, further increasing the difficulty of demolding.

Injection and Holding Times: The “Patience Test” of Prolonged Durations

Excessively long injection and holding times increase the residence time of the plastic part in the mold cavity and extend the cooling time. The plastic part undergoes more thorough heat exchange with the mold, resulting in an increased adhesion force and requiring greater resistance to be overcome during demolding.

III. Raw Materials: The “Potential Impacts” of Material Characteristics

Foreign Matter in Raw Materials: The “Quality Hazard” of Impurity Contamination

The presence of foreign matter in raw materials, such as dust, metal shavings, or other impurities, can change the fluidity and melting characteristics of the raw materials. These foreign particles may block the gate or runner during the injection molding process, affecting the normal flow of the melt, resulting in uneven filling of the plastic part and increasing the difficulty of demolding. At the same time, foreign matter can also affect the surface quality of the plastic part and reduce its service performance.

Improper Selection of Demolding Agents: The “Selection Pitfall” of Lubrication Failure

Demolding agents play a role in lubricating and reducing friction during the injection molding process. If the demolding agent is improperly selected, such as being incompatible with the raw materials, having poor lubrication effects, or leaving excessive residues, it will fail to effectively reduce the friction between the plastic part and the mold, leading to demolding difficulties. In addition, excessive residues of the demolding agent can also affect the subsequent processing and service performance of the plastic part.

Difficulties in demolding plastic mold injection-molded products are a complex issue involving multiple aspects such as plastic mold design, injection molding process control, and raw material selection. Only by thoroughly understanding these influencing factors and optimizing and improving them in actual production can demolding difficulties be effectively solved, thereby improving production efficiency and product quality.