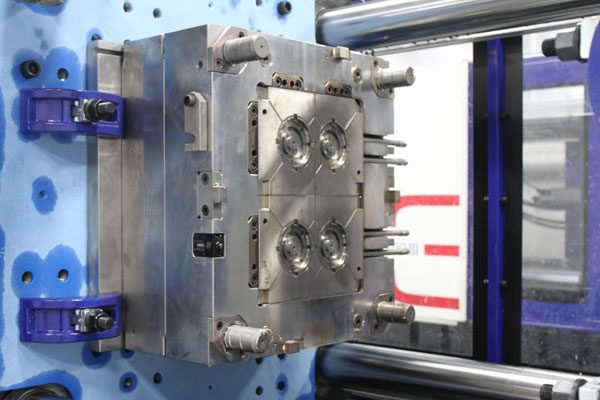

In the field of injection molding, injection molds are the core “contributors”. The working condition of injection molds is closely related to the quality of injection molding products. Molds create value during use, but they also gradually lose value over time. Therefore, operators must attach great importance to the use of injection molds and pay attention to the following key points.

Pre-use: Thorough Inspection, “Cleaning Up” for the Mold

Before officially putting an injection mold into use, a comprehensive and meticulous inspection of all parts of the mold is essential. It’s necessary to carefully check for any impurities or dirt, especially those residual impurities from plastic molding materials and the mold itself. These “unwelcome guests” may affect the mold’s normal operation and the products’ quality. Once impurities are found, cotton yarn can be used for wiping. For stubborn adhesives that are difficult to remove, timely and effective measures should be taken to ensure that the inside of the mold is clean and tidy, making full preparations for subsequent production.

Clamping Force: Precise Control, Balancing Quality and Wear

Reasonable selection of the clamping force is a crucial aspect in the use of injection molds. An appropriate clamping force can ensure that no flash is generated during the product molding process, thus guaranteeing the appearance quality and dimensional accuracy of the products. However, a higher clamping force is not always better. Excessive clamping force will impose great pressure on the transmission components, making them more prone to damage and shortening the service life of the mold. Therefore, operators need to precisely control the magnitude of the clamping force based on factors such as the product material, mold structure, and production requirements. This ensures product quality while minimizing wear on the transmission components.

Lubrication: Maintaining Smooth Operation, “Oiling Up” for the Mold

Each transmission component of an injection mold is like a gear in a precision instrument, requiring good lubrication to operate smoothly. During the use of the mold, it’s essential always to maintain the lubrication status of all components. Regularly adding an appropriate amount of lubricating oil to the transmission components can effectively reduce friction between them, lower the degree of wear, improve the operating efficiency of the mold, and extend its service life. Operators should formulate a detailed lubrication plan and strictly adhere to it to ensure that the mold is always in a well-lubricated state.

Anti-impact: Treating Gently, Safeguarding the Mold’s “Safety”

When operating an injection mold, it is strictly forbidden to use heavy objects to impact any part of the mold. Each component of the mold has its specific structure and function. Once impacted by heavy objects, the components may deform or even be damaged, seriously affecting the normal use of the mold and the quality of the products. Operators should always be cautious during the use of the mold to avoid causing unnecessary damage due to improper operation.

Here, it’s worth mentioning Dongguan Yize Mold Co., Ltd. Established in 2007, the company has been deeply engaged in the field of precision mold design and manufacturing as well as precision injection molding product production for many years. It focuses on the design, precision mold manufacturing, injection molding, assembly, and after-sales service of products such as automotive connectors, medical product injection molding, dust-free injection molding, and PFA custom injection molding, providing customers with one-stop complete solutions. If you have relevant needs, please feel free to call for consultation at +86 13302615729 (the same number for WeChat and Whatsapp).