In the field of injection mold design and manufacturing, a frequently asked question is, “What is the required cooling time for injection molds?” In fact, the cooling time for injection molds is not a fixed value but is influenced by a variety of factors, including injection molding parameters, mold materials, product part characteristics, and the mold design itself.

Injection Molding Parameters: The “Invisible Conductors” of Cooling Time and Shrinkage Rate

Injection molding parameters play a decisive role in the performance of injection-molded parts. Among the processing conditions affecting part geometry, temperature, filling parameters, cooling time, and injection speed are all crucial. These conditions are interrelated and jointly determine how the material solidifies in the mold, thereby influencing the cooling time required to meet part specifications.

For example, temperature fluctuations directly affect the fluidity and solidification speed of the material. The material may solidify slowly if the temperature is too high, leading to an extended cooling time. Conversely, if the temperature is too low, the material may solidify prematurely, affecting the internal quality of the part. Filling parameters and injection speed also interact with cooling time, collectively shaping the final form of the injection-molded part.

Therefore, close collaboration between processors and mold designers is essential. Both parties need to jointly explore and optimize the mold design based on specific molding conditions, ensuring that the cooling time settings meet both production efficiency requirements and part quality standards.

Material Properties: The “Intrinsic Genes” of Cooling and Shrinkage

Material is another key factor influencing cooling time and shrinkage rate. Each material has its unique properties, and molding conditions further alter how these properties manifest in the product. Among these, melt and mold temperatures are the two core parameters affecting the material’s cooling time and shrinkage rate.

Melt temperature determines the initial state of the material when injected into the mold. A higher temperature enhances material fluidity but may prolong cooling time. A lower temperature, on the other hand, reduces fluidity, potentially leading to underfilling or part defects. Mold temperature directly affects the cooling speed of the material in the mold. Reasonable mold temperature settings can balance cooling time and part quality, avoiding warpage or deformation caused by uneven cooling.

Mold Design: The “Precise Layout” of the Cooling System

Mold design, particularly the geometry of the part itself, has a decisive impact on how the part cools in the mold. The cooling process of a part typically proceeds from the outside in. If the part has areas with uneven wall thickness, stress concentration may occur during the cooling stage. At this time, the thinner parts will solidify faster than the thicker parts, potentially causing the part to warp and affecting the final quality of the product.

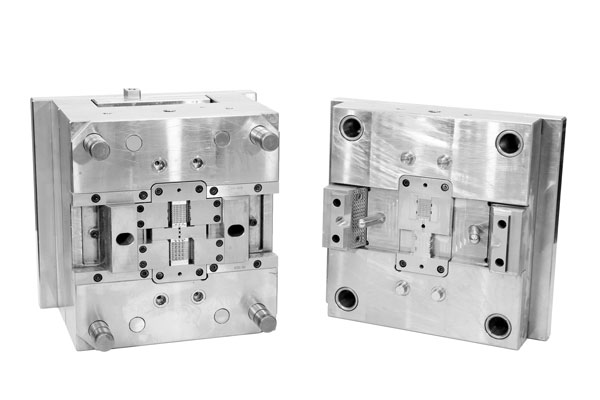

Therefore, skilled design engineers need to comprehensively consider the part geometry, the resin used, and the processing parameters to accurately grasp the cooling law of the part in the mold and design a scientific and reasonable cooling system accordingly. The cooling system usually consists of water channels running through the mold to ensure uniform and efficient cooling of the part. At the same time, mold designers must exercise caution to avoid interference between the cooling lines and the clamping system or tie bars of the molding machine, ensuring the overall stability and reliability of the mold.

Professional Assistance: The “Provider” of Efficient and Cost-Effective Solutions

In the field of injection mold design and manufacturing, Dongguan Yize Mould Co., Ltd. stands out with its rich experience and exquisite technology. As a company focusing on custom precision mold manufacturing and injection molding processing, Yize Mould has accumulated profound expertise in designing injection molds with complex molding conditions.

We understand that each injection molding project has its unique requirements and challenges. Therefore, Yize Mould combines its practical experience with cutting-edge technology to provide customers with efficient and cost-effective solutions. Whether it’s optimizing cooling time, improving part quality, or reducing production costs, Yize Mould can tailor the most suitable mold design solutions for customers with its professional team and advanced technology.

Choose Yize Mould, and choose professionalism and trust. Let us work together to create a brilliant future in the injection molding industry!