Developing new plastic molds is a systematic and rigorous process that requires following a specific sequence of steps to ensure mold quality and product performance. The following will elaborate on this procedure in detail. It can serve as both a standard operating procedure for designing and manufacturing new plastic molds and a checklist to prevent the omission of key steps during project progression.

I. Preliminary Planning

At the outset of a project, comprehensive planning is of utmost importance. It is essential to thoroughly consider the target user group of the product and the specific environment in which the product will be used. For example, if the product is a plastic item for outdoor use, factors such as weather resistance and UV resistance need to be taken into account. If it is a children’s toy, safety and ease of cleaning become crucial considerations. Simultaneously, extensive research should be conducted on suitable materials and molding methods to lay a solid foundation for subsequent work.

II. Research on Materials and Molding Methods

Conduct in-depth research on existing similar products to obtain valuable information. Pay special attention to ergonomic data, such as the operating range of the product, the required thrust, and the frequency of use. This information helps in accurately selecting materials and molding methods, ensuring that the product not only conforms to human usage habits but also meets performance requirements. For instance, for a frequently used tool handle, materials that are wear-resistant, comfortable, and have a certain degree of elasticity should be chosen.

III. Determination of Product Specifications

At this stage, try to clarify the feasible materials and processes as much as possible. Conduct a detailed estimation of the manufacturing costs of plastic molds and confirm that they are within the budget to avoid fund shortages in the later stages.

IV. Design Phase

- Preliminary Sketching: Unleash creativity and sketch various possible shapes of the product, marking details such as joints, methods for fixing sections, and potential assembly approaches. This step provides rich inspiration and directions for subsequent design.

- Scheme Selection: From multiple preliminary design schemes, comprehensively consider factors such as performance, cost, and production difficulty to determine the most suitable design scheme.

- Overall Layout: Draw an overall layout plan to clarify the relative positions and dimensional relationships of each part of the product, ensuring the rationality and coordination of the overall structure.

- Model Making: Create a product model based on the selected design scheme. The model can be a physical model or a digital model, which helps in visually identifying design issues.

- Testing and Modification: Conduct comprehensive testing on the model to check its functionality, appearance, strength, and other aspects against requirements. Modify and optimize the model according to the test results.

- Drawing Preparation: Prepare detailed drawings of plastic molds and mold components to provide precise guidance for subsequent manufacturing and processing.

V. Manufacturing and Processing

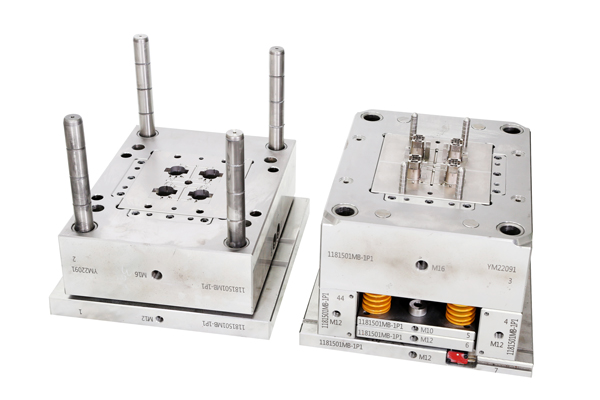

- Mold Making: According to the detailed drawings, use advanced processing equipment and techniques to manufacture plastic mold carefully. Ensure the dimensional accuracy, surface quality, and structural rationality of the molds.

- Molding and Assembly: Use the manufactured molds for molding processing to transform plastic raw materials into product components. Then, trim the molded components to remove burrs, flash, and other defects, and assemble them accurately.

- Product Assembly: Assemble the various components into a complete product according to the design requirements, ensuring an accurate and error-free assembly process and stable and reliable product performance.

VI. Testing and Evaluation

Test the assembled product in the recommended working environment to simulate actual usage scenarios. Check the product’s performance under different conditions, such as its durability, stability, and sealing properties, to ensure it meets user needs and expected usage effects.

VII. Optimization and Improvement

Based on the test and evaluation results, conduct an in-depth analysis of the product to identify areas that require improvement. Prepare detailed drawings to clearly show the improvements and re-examine and optimize the entire process from the design phase, repeating all necessary steps until the product reaches the desired quality standard.

Developing new plastic molds is an iterative and optimization process where each step is closely interconnected and mutually influential. Only by strictly following the above procedure can high-quality plastic molds and products that meet market demands be developed.