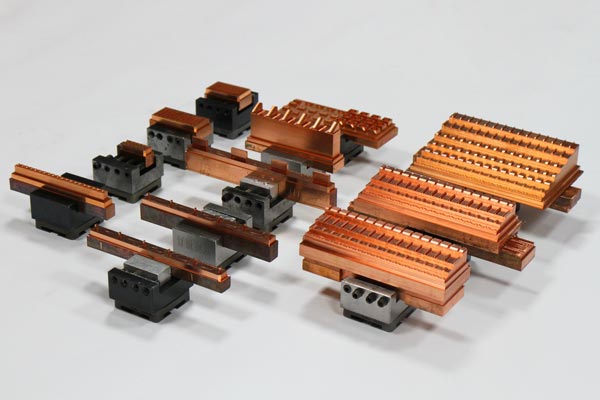

In the field of precision injection mold manufacturing, electrical discharge machining (EDM) is an indispensable key process, and the choice of electrode material directly affects machining efficiency, quality, and cost. Traditionally, copper electrodes have dominated due to their excellent electrical conductivity and machining stability, while graphite electrodes have been considered as alternatives for large-scale, low-precision scenarios. However, with advancements in material science and machining technology, the performance boundaries of graphite electrodes have continued to expand, leading to profound changes in their competitive relationship with copper electrodes. This article systematically compares the machining characteristics of the two, providing scientific electrode selection guidelines for mold manufacturing enterprises.

I. Machining Efficiency: The Integrated Rough-Finishing Advantage of Graphite Electrodes

Graphite, as a non-metallic material, has a melting point as high as 3652-3697°C and can withstand higher current densities. During rough machining, its thermal conductivity is only one-third that of copper, concentrating the heat generated by electrical discharges more effectively on the workpiece surface and significantly increasing the metal removal rate. Experimental data shows that under the same discharge area, the machining speed of graphite electrodes can reach 1.5-2 times that of copper electrodes. In medium and fine machining, the particle attachment effect of graphite forms a protective layer, further reducing electrode wear and enabling continuous “rough-to-fine” machining. In contrast, copper electrodes require frequent replacement to maintain precision, weakening their overall efficiency advantage.

II. Surface Quality: The Ultimate Precision of Copper Electrodes and the Stability of Graphite

Copper has a low electrical resistivity (1.68×10⁻⁸ Ω·m) and a dense structure, achieving mirror-like finishes below Ra0.1 μm in micro-machining, making it particularly suitable for precision molds with high surface finish requirements. However, under high-current conditions, copper electrodes are prone to thermal stress cracking, causing a sharp deterioration in surface roughness. Graphite electrodes, through particle size control (now reaching φ3 μm), achieve a stable best surface roughness of Ra0.4 μm, with more uniform discharge erosion points. In machining with roughness levels above VDI20, their grainy surface exhibits better wear resistance than the molten traces on copper electrodes. For cavities with a VDI26 (Ra2.0 μm) surface finish, graphite electrodes can complete rough and fine machining in one step, avoiding the process complexity of multiple electrode changes required for copper electrodes.

III. Machining Accuracy: Thermal Stability Determines Dimensional Control Capability

The thermal expansion coefficient of graphite (1.1×10⁻⁶/°C) is only 1/15 that of copper (17×10⁻⁶/°C). In deep and narrow rib machining, copper electrodes are prone to bending deformation due to localized overheating, requiring a thermal compensation allowance of 0.1-0.3 mm. In contrast, graphite electrodes maintain high dimensional stability, ensuring machining accuracy within ±0.02 mm without correction. For electrodes with an aspect ratio exceeding 5:1, the risk of thermal deformation significantly increases for copper electrodes, while graphite electrodes can avoid such issues.

IV. Economic Viability and Process Adaptability: The Lightweight and Integrated Advantages of Graphite

Graphite has a density (1.8-2.1 g/cm³) only one-fifth that of copper (8.9 g/cm³), reducing the spindle load of machine tools by over 60% for large-volume electrodes and avoiding machining errors caused by electrode deflection. Its ease of machining (with a cutting resistance only one-fourth that of copper) increases the manufacturing efficiency of complex electrodes by 2-3 times, and the absence of burrs after ball milling allows direct use in electrical discharge machining, eliminating manual polishing. However, the wire cutting speed of graphite is 40% slower than that of copper, and dust generated during machining requires a sealed dust removal system. In terms of installation, graphite electrodes can be fixed without holes using conductive adhesive, shortening clamping time by 30%. However, their brittleness requires avoiding lateral impacts, while the plastic deformation of copper electrodes, though hidden, can lead to batch scrapping of workpieces.

V. Cost Trends: The Competition Between Resource Constraints and Process Innovation

As a non-renewable resource, copper prices are significantly influenced by international market fluctuations, with a 45% increase from 2020 to 2023. In contrast, graphite prices have remained stable due to process optimizations (such as isostatic pressing technology), and the comprehensive cost of large electrodes is now 20%-30% lower than that of copper electrodes. With stricter environmental policies, the dust recovery costs for graphite machining are gradually decreasing, further highlighting its cost advantages.

Conclusion

Copper electrodes remain irreplaceable in micro-machining (Ra < 0.2 μm) and small-batch, high-precision scenarios. In contrast, graphite electrodes have become the preferred material for large and medium-sized mold machining due to their advantages in efficiency, stability, and cost. Enterprises need to make comprehensive decisions based on machining accuracy, batch size, and equipment conditions, achieving maximum value in electrical discharge machining through the collaborative optimization of materials, processes, and equipment.