Under the strong impetus of the technological wave, electronic products have become an indispensable part of people’s daily lives. However, the thermal issue of electronic products has always been a key bottleneck restricting their performance improvement and service life extension. In this context, injection molding technology has emerged in the field of thermal design of electronic products and plays a crucial role with its unique advantages.

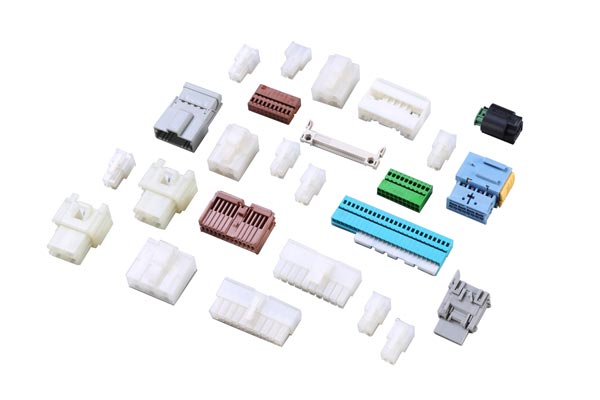

Injection molding technology is essentially an advanced manufacturing process that precisely injects thermoplastic plastics into pre-designed molds and forms the required products through cooling and solidification. In the complex system of thermal design of electronic products, injection molding technology mainly focuses on the manufacturing of thermal dissipation components, such as heat sinks and cooling fins, which cannot be formed without it.

The application advantages of injection molding technology in the thermal design of electronic products are significant. Firstly, it has powerful shape-shaping capabilities. By carefully designing the molds, injection molding technology can easily manufacture thermal dissipation components with various shapes and sizes. Whether it is a miniature cooling fin suitable for portable electronic devices or a high-performance heat sink for large-scale servers, injection molding technology can accurately achieve it. This flexibility enables the thermal dissipation components to perfectly fit the unique thermal dissipation requirements of different electronic products, providing strong support for solving diverse thermal dissipation problems. Moreover, injection molding technology can also manufacture thermal dissipation components with high thermal conductivity. Thermal conductivity is a key indicator for measuring thermal dissipation efficiency. Thermal dissipation components with high thermal conductivity can more rapidly conduct heat away, effectively improving the thermal dissipation efficiency of electronic products and ensuring their stable operation.

In addition to its excellent shape-shaping capabilities, the thermal dissipation components manufactured by injection molding technology also perform well in terms of physical properties and chemical stability. In terms of physical properties, injection molding technology can create thermal dissipation components with both high strength and high rigidity, enabling them to withstand various mechanical impacts generated during the operation of electronic products without deformation or damage. At the same time, these thermal dissipation components also have excellent heat resistance and can maintain stable performance in high-temperature environments, ensuring the continuous effectiveness of thermal dissipation functions. In terms of chemical stability, the thermal dissipation components formed by injection molding can resist the erosion of various chemicals inside electronic products and are not prone to chemical reactions, thus extending the service life of the thermal dissipation components and providing reliable protection for the long-term stable operation of electronic products.

What is even more prominent is that injection molding technology has strong compatibility and can be deeply integrated with other manufacturing technologies to form composite manufacturing processes. Taking its combination with metal processing technology as an example, through this composite process, composite thermal dissipation components that integrate the excellent thermal conductivity of metals and the strength advantages of plastics can be manufactured. The metal part can quickly transfer heat away due to its excellent thermal conductivity, while the plastic part provides a solid structural support for the thermal dissipation components with its good strength and formability. This composite manufacturing process not only significantly improves the comprehensive performance of the thermal dissipation components but also extends their service life. At the same time, it reduces manufacturing costs to a certain extent, achieving a perfect balance between performance and cost.

. Looking ahead, with the continuous progress and innovation of technology, injection molding technology will surely become more mature and perfect, bringing more high-quality, efficient, and reliable solutions to the thermal design of electronic products and helping electronic products take more solid steps in improving performance and extending service life.