In the booming development process of the injection molding industry, to enhance product quality, a series of new methods and procedures have been continuously developed and put into use. Among them, gas-assisted injection molding stands out as a unique process, bringing new changes to the injection molding field.

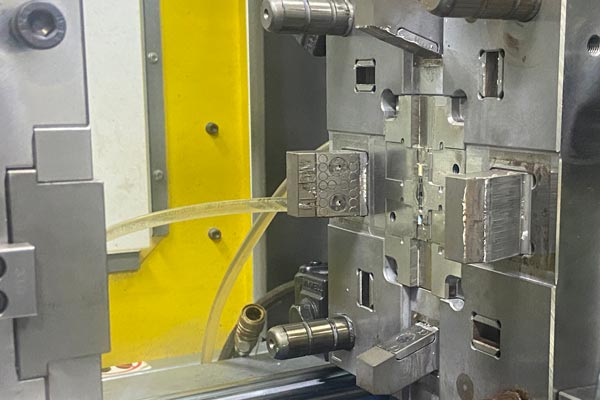

Gas-assisted injection molding is an injection molding process that uses nitrogen to form hollow channels inside an injection mold. During the molding process, nitrogen plays a crucial role by forcefully pushing the material from the core area to the edge of the mold. This process is of great significance. It not only effectively relieves the internal tension of the product, making the material distribution more uniform and reasonable, but also successfully creates streamlined surfaces, greatly improving the product’s appearance quality. At the same time, it can effectively prevent product shrinkage and ensure the dimensional stability of the product.

However, it should be noted that although gas assisted injection molding can bring significant benefits to many products, it is not a one-size-fits-all solution for all injection-molded products. A deep understanding of the potential advantages of gas-assisted injection molding is crucial for determining whether it meets one’s own needs.

Significant Advantages of Gas-Assisted Injection Molding

Enhancing Product Design and Structural Integrity

When manufacturing plastic products, maintaining the strength and integrity of parts is a top priority. In terms of product design and structural integrity, gas-assisted injection molding shows significant advantages. It breaks the limitations of traditional processes regarding wall thickness and design complexity, allowing parts with different wall thicknesses and complex designs to be perfectly integrated into a single part with high tolerance. For example, in some products that require a balance of strength and light weight, gas-assisted molding can seamlessly and flawlessly mold support structures and reinforcing ribs into the interior of the part. The entire process is smooth and natural, leaving no defects or blemishes on the product surface, ensuring both the structural strength and overall aesthetic appeal of the product.

Reducing Production Costs

Compared with traditional injection molding processes, gas assisted injection molding has obvious cost-saving advantages in the production process. Due to the assistance of gas, the clamping force required during the molding process is greatly reduced. This means that the stress borne by the mold components is also correspondingly reduced, thereby reducing the frequency of mold wear and damage. The mold components do not need to be replaced frequently, which not only reduces the procurement and maintenance costs of the molds but also reduces the production downtime caused by mold replacement, improving production efficiency and comprehensively reducing production costs.

In conclusion, gas-assisted injection molding, with its unique working principle and significant advantages, occupies an important position in the injection molding industry. Although it is not applicable to all scenarios, it can bring positive impacts on product production and quality improvement under appropriate conditions.