In the injection mold industry, whether the delivery time is appropriate has always been a major concern for customers. After all, this directly affects the progress of production plans, cost control, and the time for product launch in the market. Different injection mold manufacturers take vastly different amounts of time to produce a set of injection molds under the same quality requirements. So, how can we accurately judge whether the delivery time is appropriate? Let’s analyze it in detail below.

It’s Not True That a Longer Cycle Means Better Quality

Some customers have a misconception: the longer the mold manufacturing cycle, the more delicate the workmanship and the better the quality. This often reflects the professional level of the mold factory. Some unprofessional mold factories, due to a lack of mature technology and efficient management, encounter numerous problems during the production and manufacturing process, resulting in a longer time required to complete mold production. Moreover, because of their poor technical skills, the molds are prone to problems during use, and subsequent repairs also take up a lot of time. This not only disrupts the customer’s production schedule but may also increase additional costs.

A Too-Short Cycle Hides Risks

Of course, a shorter mold manufacturing time is not necessarily better. The manufacturing of injection molds is a complex and rigorous process, covering multiple links such as mold design, material selection, processing and manufacturing, and assembly and debugging. Each link requires careful operation and strict quality control. Only by allowing sufficient time can we ensure that the quality and performance of the mold meet the standards. Suppose a manufacturer compresses the time for each process to rush the schedule. In that case,

it is likely to lead to design defects, insufficient processing accuracy, and other problems in the mold, which in turn will affect the quality of the products and production efficiency.

There Are Rules for a Reasonable Delivery Time

Professional injection mold manufacturers, with years of experience accumulation and technical precipitation, have precise control over the mold manufacturing time. Generally speaking, the normal time for manufacturing a set of injection molds is 50 – 65 days, but this is not absolute and needs to be adjusted according to the difficulty of the mold. For conventional molds, a minimum of about 30 days is required for manufacturing; and even for very complex molds, the manufacturing time generally does not exceed 75 days. Only within this reasonable time frame can the manufacturer complete the work of each link in an orderly manner and produce high-quality injection molds.

A High-Quality Manufacturer Is Trustworthy

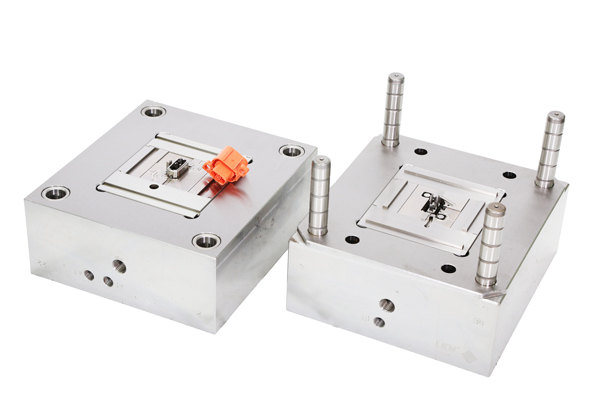

Here, we would like to recommend a professional injection mold enterprise – Dongguan Yize Mould Co., Ltd. Founded in 2007, the company has been focusing on the design and manufacturing of precision molds and the production of precision injection molded products for many years. It has strong technical strength and rich industry experience, and can provide a complete set of solutions from product design, precision mold manufacturing, injection molding and assembly to after-sales service for fields such as automotive connectors, medical product injection molding, clean room injection molding, and PFA custom injection molding.

If you are troubled by the issue of the injection mold delivery time or have related business needs, please feel free to call for consultation. Contact number: +86 13302615729 (same for WeChat and Whatsapp). Dongguan Yize Mould Co., Ltd. will serve you wholeheartedly!