In the field of injection molding, precisely controlling barrel temperature is a core factor in ensuring product quality and enhancing production efficiency. Whether the barrel temperature can be stably maintained within the set range as required by the injection molding process not only affects the utilization rate of plastic materials but also directly impacts the quality of the final products. Therefore, delving into how to effectively control the barrel temperature is of great significance for promoting the optimization and upgrading of injection molding technology.

Control Challenges under Complex Operating Conditions

During injection molding production, multiple factors interact, posing significant challenges to barrel temperature control. Different plastic products have varying pre-plasticizing volumes and production cycles, while the ambient temperature is also in a state of dynamic change. These factors result in different parameters for the temperature object of the material barrel. What’s more, there is a strong coupling phenomenon between the temperature controls of different sections of the material barrel, making it extremely difficult to achieve complete decoupling control. Additionally, this object exhibits a large time-delay characteristic. When conventional control methods are applied, large overshoots and oscillations often occur, making it difficult to achieve high-precision temperature control. Therefore, developing adaptive temperature control strategies is urgently needed.

Key Points of Multi-element Temperature Control

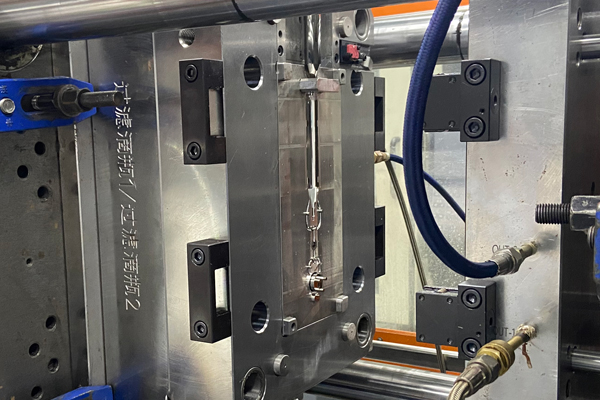

In the injection molding process, temperature control covers three key parts: the barrel, the nozzle, and the injection mold.

- Precise Control of Barrel Temperature

Barrel temperature refers to the surface heating temperature of the barrel. Due to the relatively thick wall of the barrel, the selection of thermocouple detection points is crucial. Temperature curves obtained from different detection points vary significantly. If the detection points are improperly selected, it will lead to inaccurate temperature control. To obtain stable temperature curves and improve temperature control accuracy, the dual-point parallel detection method is an ideal choice. That is, thermocouples are simultaneously installed on the surface and deep inside the barrel. By comprehensively analyzing the data from the two points, the internal temperature changes of the barrel can be more accurately grasped, providing a reliable basis for temperature control. - Fine Adjustment of Nozzle Temperature

Nozzle temperature has a decisive influence on the flow characteristics of the plastic melt and directly affects the quality of the products. When the plastic melt passes through the nozzle, improper temperature control may lead to poor melt fluidity, which in turn causes surface defects and dimensional deviations in the products. Therefore, extremely high control accuracy is required for nozzle temperature. High-precision temperature sensors and advanced control algorithms need to be used to ensure that the nozzle temperature remains within the optimal range at all times. - Scientific Regulation of Mold Temperature

Mold temperature refers to the surface temperature of the mold cavity in contact with the products. It has a significant impact on the filling, cooling, and packing processes. An appropriate mold temperature helps the plastic melt fill the mold smoothly, reduces the internal stress of the products, and improves their dimensional stability and surface quality. During the cooling stage, a reasonable mold temperature can accelerate the cooling speed of the products and shorten the production cycle. During the packing stage, a stable mold temperature ensures uniform product density and avoids defects such as shrinkage cavities and sink marks. Therefore, scientific regulation of mold temperature is an indispensable part of the injection molding process.