In the highly specialized and fiercely competitive field of vehicle manufacturing, lightweight design has emerged as a crucial research direction driving continuous industry development and innovation. Industrial plastics, with their unique and exceptional performance advantages, play a pivotal and indispensable role in this process. The following will delve into the multiple significant contributions made by industrial plastics in vehicle manufacturing.

Significantly Reducing Overall Weight and Enhancing Energy Utilization Efficiency

One of the most prominent features of industrial plastics is their lightweight nature. In the manufacturing of various vehicles such as cars, airplanes, and trains, replacing traditional metal materials with industrial plastics can lead to a substantial reduction in overall weight. This change has far-reaching implications for improving vehicle performance. Taking cars as an example, a lighter body reduces the load on the engine, thereby enhancing fuel efficiency and cutting energy consumption. In the aviation sector, a lighter aircraft means carrying less fuel, which not only reduces operating costs but also decreases carbon emissions, aligning with the current global demand for green environmental protection. Similarly, for trains, lightweight design helps increase running speed and energy utilization efficiency, strengthening their competitiveness in the market.

Excellent Formability and Plasticity, Facilitating Complex Component Design

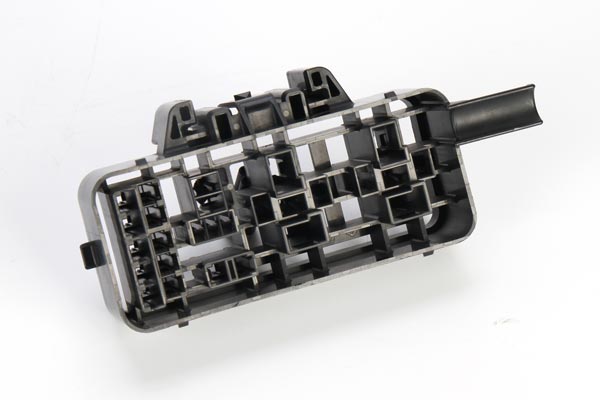

Industrial plastics boast excellent formability and plasticity, providing a vast scope for their application in vehicle manufacturing. Through advanced processes such as mold injection molding and pressing, various shapes and structures of components can be easily manufactured with high precision and stable dimensions. This characteristic enables designers to break free from the limitations of traditional materials during the vehicle design process and more flexibly conceive and realize the design of various complex components. For instance, in automotive interior design, industrial plastics can be used to create uniquely shaped and smoothly contoured control panels and decorative parts, enhancing the overall aesthetics and technological sense inside the car. Moreover, precise molding processes ensure tight fitting between components, improving the overall mechanical performance and safety of the vehicle and reducing failures and accidents caused by loose parts or assembly errors.

Superior Corrosion Resistance and Impact Resistance, Ensuring Component Service Life and Passenger Safety

Vehicles inevitably face various complex and harsh environmental conditions during use, such as rain erosion, sun exposure, and significant temperature variations. Industrial plastics have excellent corrosion resistance, effectively resisting damage from these environmental factors and extending the service life of components. Compared with metal materials, industrial plastics do not rust due to oxidation, reducing the frequency of component damage and replacement and lowering maintenance costs. Additionally, industrial plastics exhibit outstanding impact resistance. In the event of a collision or other accidents, components made of industrial plastics can absorb and dissipate impact energy, reducing harm to passengers and providing reliable protection for their lives. For example, automotive bumpers made of industrial plastics can buffer the impact force during minor collisions, protecting the vehicle body and passengers while reducing repair costs.

Exceptional Sound Insulation and Shock Absorption Performance, Improving Passenger Comfort

In vehicles such as cars and airplanes, noise and vibration are important factors affecting passenger comfort. Industrial plastics have good sound insulation and shock absorption properties, effectively addressing this issue. By using industrial plastic materials in key parts of vehicles, such as sound insulation covers in car engine compartments and cabin wall interiors in airplanes, the transmission of noise can be significantly reduced, and the impact of vibration on passengers can be minimized. Passengers can enjoy a quieter and more stable environment during their journey, enhancing their travel experience and satisfaction. This is of great significance for improving the market competitiveness and brand image of vehicles.

In conclusion, in the context of lightweight design, industrial plastics play a crucial role in vehicle manufacturing due to their multiple excellent properties. They not only help reduce the overall weight of vehicles and improve energy utilization efficiency but also enhance mechanical performance, durability, and passenger comfort. With the continuous progress of science and technology and the ongoing development of materials science, the application prospects of industrial plastics in vehicle manufacturing will be even broader, expected to bring more opportunities and breakthroughs for industry innovation and development.