In today’s fiercely competitive market environment, the level of production efficiency often determines whether an enterprise can stand out and gain an edge in the intense competition. High – efficiency production means producing more high – quality products in a shorter time, which is the key to enhancing a company’s core competitiveness. This article focuses on the premise of determined mass production and delves into how to improve the mold injection cycle by using existing or newly designed injection molding machines and molds, providing practical ideas for enterprises to achieve efficient production.

1. Optimize the Clamping Process to Improve Clamping Efficiency

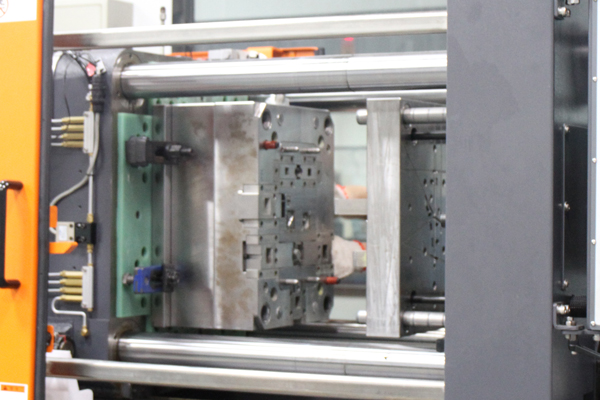

The injection cycle of an oil – hydraulic driven injection molding machine usually starts from mold closing and ends with the next mold closing. The mold – closing process is generally divided into four stages: fast mold closing, slow mold closing, low – pressure mold protection, and high – pressure mold locking. For recently designed toggle – type injection molding machines, they are generally equipped with regenerative mold – closing oil circuits, which are designed to achieve higher mold – closing speeds. However, in practical applications, it is necessary to ensure that the mold is not subject to excessive impact. Under this major premise, using the regenerative mold – closing oil circuit can significantly improve the mold – closing efficiency and thus shorten the injection cycle.

2. Precisely Control the Clamping Force to Shorten the Clamping Time

Rationally using a low clamping force that can ensure no flash on the finished product is an effective way to shorten the time required for the high – pressure mold – locking stage. When a low clamping force is used, it not only reduces the time spent in the high – pressure mold – locking stage but also protects the mold, the tie – bars of the injection molding machine, and the mold plate, effectively extending the service life of these key components, reducing equipment maintenance costs, and achieving a dual improvement in production efficiency and equipment life.

3. Enhance Mold Heat Exchange to Accelerate the Cooling Process

In the mold injection production process, the mold can essentially be regarded as a heat exchanger. It continuously removes the heat of the molten plastic through water channels, and a well – designed mold can significantly improve the heat exchange efficiency. When conditions permit, using ice water for cooling can further shorten the “cooling time.” Because the low – temperature characteristic of ice water enables it to absorb heat more quickly, accelerating the cooling and solidification of the product, and thus providing strong support for shortening the entire injection cycle.

4. Innovate the Ejection Method to Increase the Ejection Speed

For small injection molding machines with low ejection force requirements, the pneumatic ejection method has a higher ejection speed compared to the traditional hydraulic ejection method. And the electric ejection method is even faster than the pneumatic ejection method. In addition, innovations can be made in mold design. For example, the mold can be designed to have the ejection action directly driven by the mold – opening action instead of relying on the ejection device on the injection molding machine. This design can reduce the intermediate links in the ejection process, improve the ejection efficiency, and thus shorten the injection cycle.

5. Optimize the Ejection Retraction Operation to Reduce Ejection Time

When dealing with some finished products that require multiple ejections, the vibration ejection function of the injection molding machine can be used. In this way, the ejector pins do not need to fully retract each time, effectively shortening the time spent on multiple ejections. This optimized ejection retraction operation can further improve production efficiency while ensuring product quality, and further optimize the injection cycle.

If you are deeply interested in our services or need any technical support, please feel free to call us at: 13302615729. We are enthusiastic about sharing our professional insights in the field of mold injection molding with you and providing cost – effective and high – precision mold injection molding solutions that meet your needs, and working together to create a bright future of efficient production.