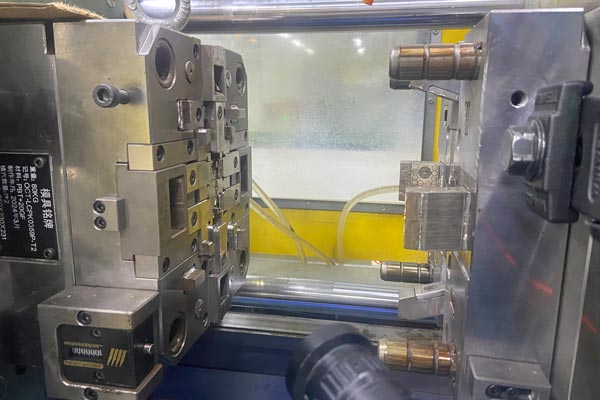

In the precision landscape of the manufacturing industry, injection mold processing holds a pivotal position. It not only ensures the efficient molding of products but also plays a decisive role in their quality and performance. Below, we will delve into the key functions of injection mold processing and the unique characteristics of its products.

Key Functions of Injection Mold Processing

1. Automatic Calibration Function of the Push Rod Fixed Plate

The automatic calibration device for the push rod fixed plate acts as an unsung hero in the smooth operation of injection molds. Installed adjacent to the reset rod, it swiftly and precisely pulls the rocker arm back to its original position after the injection mold ejects the plastic product. This process is akin to a meticulously choreographed mechanical dance, ensuring that the mold returns to its exact initial position in every cycle. This guarantees the continuity and stability of production, significantly reducing the likelihood of defective products caused by mold misalignment and thereby ensuring consistent product quality.

2. Precise Positioning Function

In the complex structure of injection molds, the precise positioning function serves as a “compass,” providing crucial guidance for accurate mold forming. Especially during side core pulling operations, the precise positioning of guide sliders is of utmost importance. By working in tandem with stop blocks, this function ensures that the sliders move strictly along the predetermined trajectory during core pulling and resetting, accurately controlling the position and angle of core pulling. This guarantees the forming precision of the side surfaces of plastic products, enabling them to perfectly match the design intent and meet the requirements for complex structures and fine dimensions.

3. Auxiliary Driving Force Function

The movable plates, runner push plates, and other movable components in injection molds are like the “dynamic cells” of mold operation. Their smooth movement relies on the support of auxiliary driving forces. Through ingenious design and layout, injection mold processing provides stable and reliable auxiliary driving forces for these movable components, ensuring that they can perform actions according to the predetermined rhythm and force during the injection molding process. This facilitates the smooth demolding of plastic products and the precise control of runners. This function not only enhances the automation level of the mold but also reduces manual intervention, further improving production efficiency and product quality.

Product Characteristics of Injection Molds

1. Spring Characteristics

In the composition of injection molds, springs are indispensable key components, with round springs and rectangular frame springs being the common types. Compared to traditional circular springs, rectangular frame springs offer significant advantages. Their unique structural design endows them with greater elasticity, enabling them to quickly recover their original shape even under substantial pressure. This provides a strong and stable rebound force for various actions of the mold. Moreover, rectangular frame springs exhibit excellent fatigue resistance. During long-term, high-frequency use, they are less prone to elastic failure, greatly extending the service life of the mold and reducing the costs associated with mold repair and replacement due to spring damage. This provides a solid guarantee for the stable production of enterprises.

2. Design Characteristics

The design process of injection mold processing is akin to a well-planned campaign, full of challenges and opportunities. Notably, a large amount of preliminary design work for injection mold processing often has to be carried out simultaneously with the still-imperfect product design. This is like constructing a precise building on a vague blueprint, where mold designers need to rely on their rich experience and professional knowledge to make forward-looking designs and plans with limited information and uncertain factors. However, as product design gradually improves and customer requirements continue to change, the later-stage design of injection mold processing may require extensive modifications. This process is not a simple adjustment but necessitates a re-evaluation of costs, comprehensively considering the impact of modifications on mold structure, production cycle, and product quality. Through continuous improvement and optimization, it ensures that the final injection molding mold can perfectly meet customer production requirements and achieve high-quality and efficient production of products.

3. Design Flexibility in Response to Potential Errors

Since potential errors are inevitable in the design process of injection mold processing products, this requires mold designers to possess a high degree of flexibility and adaptability. When design issues are identified, designers need to respond promptly and redesign or modify parts of the mold. This process not only tests the designer’s professional skills but also reflects their profound understanding of customer needs and their unwavering pursuit of product quality. Through continuous adjustments and optimizations, it ensures that the injection molding mold can precisely meet customer production requirements, providing customers with high-quality and reliable product solutions and helping them stand out in the fierce market competition.

Injection mold processing, with its unique functions and outstanding product characteristics, has become an indispensable and important link in modern manufacturing. By gaining a deep understanding of its key functions and product characteristics, we can better grasp the core elements of injection mold processing and provide strong support for the high-quality development of enterprises.