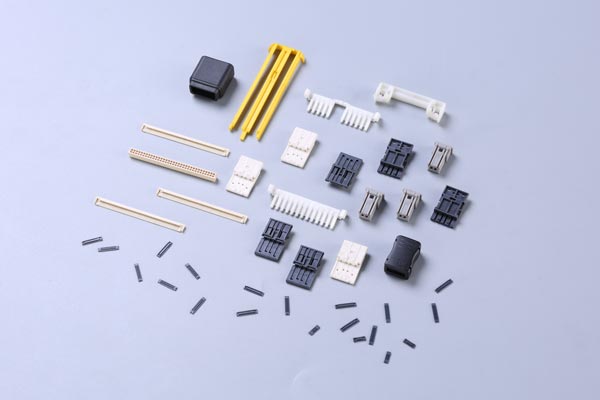

【Introduction】

In the field of precision electronics manufacturing, injection molding is not merely a processing method for exterior components but a core process that determines the precision and reliability of internal structural parts. The setting of process parameters is not a matter of simple empirical trial-and-error, but a systematic engineering challenge based on material rheology and thermodynamics. Any deviation in parameters can trigger product warping, dimensional instability, or even electrical performance failure. This article provides an in-depth analysis of the specific impact of injection molding parameters—temperature, pressure, time, and mold thermal management—on the comprehensive performance of electronic products, offering theoretical support for achieving high-yield production.

【Section 1: Temperature Parameters – Balancing Material Rheology and Thermal Degradation】

Temperature is the most sensitive variable in the injection molding process, directly governing the melting, mold filling, and cooling/setting of polymers.

- Fluidity Control: Excessively high melt temperatures can lead to material thermal degradation and oxidation, resulting in yellowing, black spots, or attenuation of mechanical properties. Conversely, temperatures that are too low cause a drastic drop in fluidity, leading to short shots (incomplete filling) or visible weld lines.

- Internal Stress Management: Improper temperature control can cause the “freezing” of molecular chain orientation, leaving high residual internal stress within the product. For electronic products, this not only affects surface gloss but can also lead to cracking during subsequent use due to stress release, severely threatening the soldering reliability and service life of electronic components.

【Section 2: Pressure Parameters – The Key to Densification and Dimensional Precision】

Injection pressure (including injection and holding pressure) determines the filling speed and packing effect of the melt within the cavity.

- Risks of Over-Pressure: Excessive injection pressure easily produces “flash” (burrs) and traps gas in cavity corners, forming bubbles or voids. This poses a fatal insulation hazard for high-voltage electronic components. Additionally, extreme clamping force can cause micro-deformation of precision molds, affecting product dimensional tolerances.

- Risks of Under-Pressure: Insufficient pressure results in inadequate holding/packing, leading to sink marks or uneven density. This not only compromises structural strength but also causes excessive clearance gaps during assembly, resulting in looseness or poor contact in electronic products.

【Section 3: Time and Mold Temperature Parameters – The Trade-off Between Crystallinity and Efficiency】

The injection cycle (time) and mold temperature are often overlooked yet critical auxiliary parameters.

- Time Effects: If the holding time is too short, the gate may not freeze before demolding, causing material backflow and dimensional spring-back. Insufficient cooling time leads to deformation during ejection. Conversely, an overly long cycle improves performance but sacrifices production capacity and cost-efficiency.

- Mold Temperature Impact: Mold temperature directly dictates the cooling rate and crystallinity of the melt. For hygroscopic engineering plastics (such as PA and PBT), low mold temperatures can cause surface fogging or silver streaks, directly degrading electrical insulation performance. Precise mold temperature control effectively reduces product warpage, ensuring the flatness required for PCB assembly.

【Conclusion】

In summary, injection molding process parameters constitute a complex, coupled system. To ensure the high performance and reliability of electronic products, enterprises must abandon “empiricism” and adopt a scientific Design of Experiments (DOE) methodology. This involves multi-parameter collaborative optimization tailored to specific material properties, product geometry, and usage environments. Only by precisely locking the process window can companies achieve the commercial goals of quality stability while reducing costs and increasing efficiency.