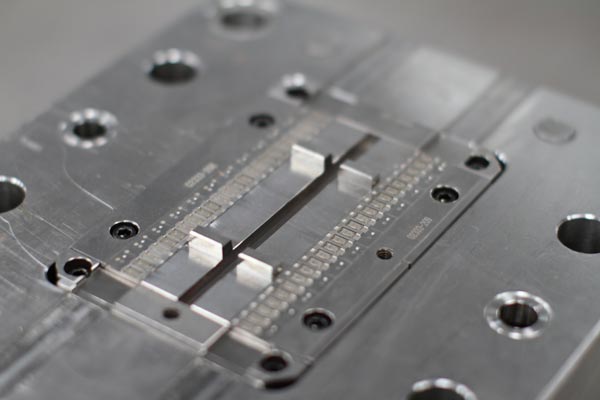

Rust on injection molds is a relatively common defect in the industry. It should be made clear that this is not due to quality issues with the stainless steel sheets themselves. Next, this article will delve into the specific causes behind the rusting of injection molds.

I. Corrosive Gases Generated from the Volatilization of the Melt

Some raw materials generate volatile gases when heated. These gases are often corrosive and can have a strong erosive effect on injection molds. When the equipment stops operating, if the injection molds are not properly handled, the residual corrosive gases will continue to act on the mold surface, accelerating the corrosion process.

To effectively address this issue, after the equipment stops working, the injection molds should be thoroughly cleaned immediately to ensure there are no residues on the surface. Once cleaned, close the molds to reduce the impact of the external environment. If the molds are not going to be used for an extended period, apply anti-rust oil inside the mold cavities to form a protective film that isolates the mold from direct contact with the air. At the same time, when closing the molds, apply unsalted butter to key parts and block the sprue gates to further enhance the mold’s anti-rust ability.

II. Problems Caused by Cooling Circulating Water

During the injection molding process, cooling circulating water is typically used to control the mold temperature. This results in a high level of humidity around the molding equipment, with water vapor being prevalent. When the mold temperature is cooled below the dew point, the moisture in the air will condense into water droplets on the mold surface. If these water droplets are not wiped off promptly, the mold surface will remain damp for a long time, which can easily lead to rusting.

Especially after the molds stop working, due to temperature changes, the rate of condensation water formation speeds up, further increasing the risk of mold rusting. Therefore, when terminating the molding operation, be sure to turn off the cooling circulating water system immediately and use a dry cleaning cloth to thoroughly wipe the mold surface to keep it dry, thereby reducing the likelihood of rusting.

III. Carbides Generated during the Molding Process

After long-term continuous operation, injection molds undergo a series of complex chemical reactions under high-temperature and high-pressure conditions in the molding process. The raw materials dissolve and transform to generate carbides. These carbides have high hardness and reactivity, which can cause wear, erosion, and even rusting on the mold surface.

Once carbides are found on the mold surface, immediate action should be taken to clean them up. Professional cleaning tools and cleaning agents can be used to carefully clean the mold surface to ensure that the carbides are completely removed. At the same time, to prevent the recurrence of carbides, the molding process parameters should be optimized and adjusted, such as reasonably controlling the temperature, pressure, and molding time, to reduce the generation of carbides at the source and ensure the normal use and extended service life of the molds.

Rust on injection molds is caused by a combination of multiple factors. In actual production, operators should fully understand these causes and take targeted preventive and handling measures. They should also strengthen the daily maintenance and care of the molds to ensure that injection molds are always in good working condition, improving production efficiency and product quality.