In the grand landscape of the manufacturing industry, Metal Injection Molding (MIM) is like a shining new star. With its unique charm and powerful strength, it is bringing unprecedented changes to numerous industries. It breaks through the limitations of traditional metal processing methods, cleverly combining metal materials with injection molding processes to open up a new manufacturing path that is efficient, precise, and flexible.

Definition and Principle of Metal Injection Molding

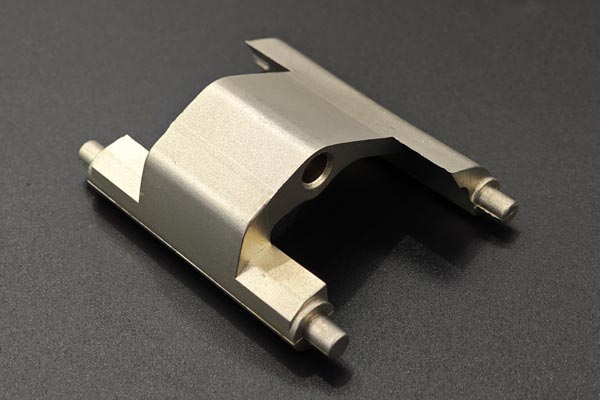

MIM is a molding method that injects a plasticized mixture of metal powder and its binder into a mold. Its core principle integrates two major technologies: plastic injection molding and powder metallurgy.

First, carefully selected metal powder is uniformly mixed with thermoplastic plastics, paraffin, and other binders in a certain proportion. Through heating and stirring, the metal powder is evenly dispersed in the binder to form a feedstock with good fluidity. This process is similar to mixing fine sand with glue, allowing the fine sand to flow freely under the binding of the glue. Next, the feedstock is heated to an appropriate temperature to reach a flowing state and then injected into a precision mold cavity, just like injecting plastic. In the mold cavity, the feedstock cools and solidifies, forming a blank with a certain shape and size. This step is extremely similar to plastic injection molding. Finally, through subsequent processing steps such as debinding and sintering, the binder in the blank is removed, allowing the metal powder particles to sinter together and form a dense metal part. The debinding process is like removing the “impurities” from the blank, while sintering is like “welding” the metal powder into a whole, giving the part its final strength and performance.

Significant Advantages of Metal Injection Molding

High Precision and Complex Shape Manufacturing Capability

Metal Injection Molding can achieve extremely high dimensional accuracy and complex geometric shape manufacturing. Traditional metal processing methods such as casting, forging, and machining often face many challenges when manufacturing complex-shaped parts, which may require multiple processes and complex tooling and fixtures. In contrast, Metal Injection Molding only needs to design a set of precision molds to form complex-shaped, high-precision parts in one go, greatly reducing subsequent processing steps and improving production efficiency and product quality. For example, when manufacturing watch parts and medical device components that have extremely high requirements for precision and shape, Metal Injection Molding technology shows unparalleled advantages.

High Material Utilization Rate

In traditional metal processing, a large amount of material is wasted in the form of chips and scrap, resulting in a relatively low material utilization rate. MIM, on the other hand, adopts near-net-shape technology, which can maximize the utilization of metal powder and increase the material utilization rate to over 95%. This not only reduces production costs but also conforms to the concept of sustainable development, reducing the consumption of raw materials and environmental pollution.

Suitable for Mass Production

The Metal Injection Molding process has a high degree of automation and continuity, enabling large-scale and efficient production. Once the mold and process parameters are determined, a large number of identical parts can be quickly and stably produced through injection molding machines, with a production efficiency far higher than that of traditional processing methods. This is of great significance for meeting the market’s demand for a large number of standardized parts, significantly shortening the product production cycle and improving the market competitiveness of enterprises.

Ability to Process a Variety of Metal Materials

Metal Injection Molding technology is applicable to a variety of metal materials, including iron-based, nickel-based, copper-based, and titanium-based alloy materials. This enables it to meet the diverse performance requirements of different industries for parts. For example, in the aerospace field, high-strength and high-temperature-resistant titanium alloy parts are required; in the electronics industry, copper alloy parts with good electrical conductivity and thermal conductivity are needed. Metal Injection Molding technology can select appropriate metal materials according to different application scenarios to manufacture parts with excellent performance.

Application Fields of Metal Injection Molding

3C Electronics Industry

In 3C electronic products such as smartphones, tablets, and laptops, MIM parts are widely used. For example, the middle frames, buttons, and camera brackets of mobile phones are manufactured using Metal Injection Molding processes. These parts not only have high precision and a beautiful appearance but also meet the requirements of electronic products for part strength, heat dissipation, and electromagnetic shielding.

Automotive Industry

The automotive industry has extremely high requirements for the precision, reliability, and lightweight of parts. MIM technology can manufacture automotive engine components, transmission system parts, and sensor housings, improving the performance and safety of automobiles while reducing their weight and energy consumption.

Medical Device Field

The medical device field has very strict requirements for the precision, biocompatibility, and cleanliness of parts. MIM technology can manufacture complex-shaped and high-precision medical device components such as surgical instruments and implants, providing strong support for the development of the medical industry.

Aerospace Field

The aerospace field has extremely demanding requirements for the performance of parts, which need to have high strength, high-temperature resistance, and corrosion resistance. Metal Injection Molding technology can manufacture key components such as turbine blades and combustion chamber parts for aerospace engines, contributing to the development of the aerospace industry.

Metal Injection Molding, as an advanced manufacturing technology, is gradually becoming an important direction in the development of the manufacturing industry with its unique advantages and wide application fields. With continuous technological progress and innovation, MIM will play an important role in more fields and drive the manufacturing industry towards higher precision, higher efficiency, and more green and sustainable development.