Metal insert molding holds a crucial position in the manufacturing industry as a unique molding process. It refers to the process of skillfully embedding metal objects during plastic injection molding, enabling the molten material to bond tightly with the inserts and ultimately form an integrated product. This process combines the advantages of metal and plastic, providing strong support for enhancing product performance and expanding functionality. So, why is metal insert molding favored by numerous industries? The following will elaborate on its advantages from multiple aspects.

Diverse Material Integration to Meet Complex Requirements

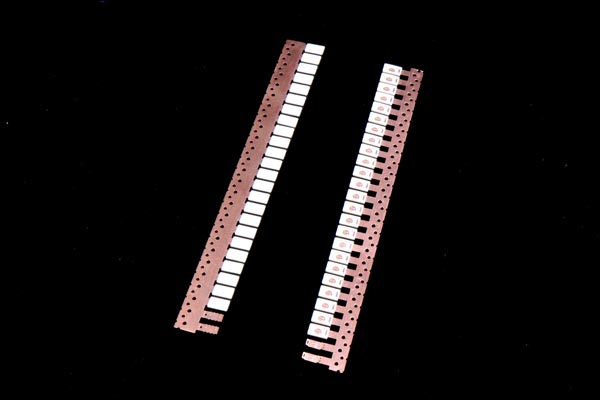

In terms of injection molding materials, metal insert molding demonstrates great flexibility. It is not only suitable for plastic materials but also capable of achieving a perfect combination with various other materials, such as metal inserts, pins, copper nuts, iron sheets, steel balls, and fibers. This multi-material injection molding approach can fully leverage the characteristics of different materials, meeting the complex requirements of products in different working environments. For example, in some products that require both high strength and excellent insulation performance, metal inserts can provide strong structural support, while plastic materials can achieve outstanding insulation effects. The two complement each other to create products with superior performance.

Unique Mold Structure to Improve Production Efficiency

The vertical injection mold structure is a distinctive feature of metal insert molding, which adopts a design of one front mold paired with two rear molds. This unique structure lays the foundation for subsequent efficient production. In actual production, vertical multi-material injection molding exhibits significant advantages. The turntable of the injection molding machine can rotate 180 degrees, allowing the two rear molds to quickly swap positions. This design cleverly achieves production continuity. When one rear mold is completing injection molding and performing operations such as mold opening and part removal, the other rear mold can simultaneously prepare for mold closing and injection molding, greatly shortening the production cycle, improving overall production efficiency, and effectively reducing production costs.

One-Step Molding Process to Simplify Production Procedures

Metal insert molding realizes one-step injection molding of plastic encapsulating metal inserts, greatly simplifying the production process. During production, there is no need to manufacture each component separately and then perform cumbersome assembly work as in traditional methods. Only after the inserts pass the inspection, they are precisely placed into the mold by manual or robotic arms, followed by injection molding and encapsulation production. This one-step molding process not only reduces production links and the quality issues caused by improper assembly but also improves the overall precision and consistency of the products, providing a strong guarantee for high-quality product production.

Metal insert molding, with its advantages such as diverse material integration, unique mold structure, and one-step molding process, has been widely applied in many fields. With the continuous development and innovation of the manufacturing industry, it is believed that the metal insert molding process will continue to be optimized and upgraded, bringing more high-quality and efficient production solutions to more industries.