Metal Injection Molding (MIM) is an advanced manufacturing technology that involves mixing metal powder with a binder, injecting the mixture into a mold to form green parts, and then obtaining final metal parts through debinding and sintering. The quality of MIM mold design and processing directly impacts the accuracy, performance, and production efficiency of the final products. The following are several key aspects to consider during MIM mold design and processing.

1. Mold Material Selection

The selection of mold materials for MIM is of utmost importance because the mold needs to withstand the high-pressure injection of the feedstock (a mixture of metal powder and binder) and the high-temperature sintering process. The metal powder in the feedstock is highly abrasive, so the mold material must possess high hardness, excellent wear resistance, and good thermal conductivity. Commonly used mold materials include tool steels and cemented carbides. For high-precision, long-life molds, specially surface-treated tool steels, such as those subjected to surface quenching or nitriding, can also be considered to enhance wear and corrosion resistance.

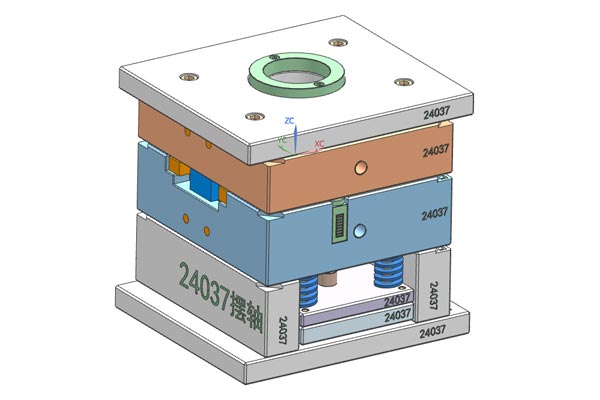

2. Mold Structure Design

2.1 Molding Part Design

- Shrinkage Consideration: MIM parts undergo shrinkage during both injection molding and debinding-sintering, with a relatively large shrinkage rate (typically 15% – 22%). Therefore, during mold design, this factor must be fully considered, and the mold dimensions should be optimized through precise calculation of the sintering shrinkage rate to ensure the dimensional accuracy of the final products.

- Draft Angle: Due to the relatively poor plasticity and rigidity of MIM parts, they are prone to surface damage during demolding. Hence, an appropriate draft angle (usually 1° – 3°) should be added to the mold design to facilitate smooth part removal.

- Cavity Roughness: The cavity roughness of MIM molds requires a high standard, generally Ra0.4, to ensure a smooth surface finish of the products.

2.2 Gating System Design

- Gate Location and Size: The location and size of the gate directly affect the filling behavior of the feedstock and the quality of part molding. A reasonable gate design can reduce molding defects such as air pockets, shrinkage cavities, and weld lines. It is generally advisable to use circular-section runners to minimize pressure loss and shorten the runner length to reduce the residence time of the feedstock in the runners.

- Runner Balance: For multi-cavity molds, the runner design must be balanced to ensure uniform filling of each cavity. This can be achieved by adjusting the cross-sectional area and length of the runners.

2.3 Cooling System Design

- Cooling Efficiency: The cooling system is designed to promptly remove the heat generated during the molding process from the mold, preventing mold overheating and damage while improving production efficiency. An efficient cooling system should ensure uniform temperature distribution across the mold, avoiding local overheating or overcooling that could cause deformation.

- Conformal Cooling Technology: Conformal cooling technology, which involves manufacturing molds with complex internal cooling channels through 3D printing, can significantly enhance cooling efficiency and shorten the molding cycle.

2.4 Demolding System Design

- Ejection Mechanism: The ejection mechanism design for MIM parts must be comprehensive and balanced to prevent deformation or damage during part removal. The location and quantity of ejector pins should be reasonably arranged based on the shape and size of the parts.

- Demolding Temperature and Speed: The control of demolding temperature and speed is also crucial. Excessive demolding temperature or speed can lead to part deformation or damage.

3. Mold Processing Accuracy

The processing accuracy of the mold directly affects the dimensional accuracy and surface quality of the products. Therefore, high-precision processing equipment and techniques should be employed during mold processing to ensure that the mold’s dimensional tolerances and surface roughness meet the design requirements. Additionally, the mold should be regularly inspected and maintained to promptly detect and repair any defects generated during processing.

4. Process Parameter Control

The MIM process involves multiple key steps, including injection molding, debinding, and sintering. The process parameters at each step need to be precisely controlled to ensure the stability of the production process and the consistency of the products.

- Injection Molding Parameters: Parameters such as injection pressure, injection speed, mold temperature, and holding pressure time should be optimized based on the flowability of the feedstock and the complexity of the part shape. Excessive injection pressure or speed can lead to high internal stresses in the parts, while insufficient parameters may result in incomplete filling.

- Debinding and Sintering Parameters: Parameters such as temperature, time, and atmosphere for debinding and sintering should be optimized according to the material properties to ensure the density, dimensional accuracy, and mechanical properties of the products. For example, insufficient debinding temperature or time may lead to incomplete debinding, affecting subsequent sintering quality, while excessive sintering temperature or time can cause part deformation or coarse grain growth.

5. Mold Maintenance and Management

Mold maintenance and management are crucial for ensuring the stability of MIM production. A comprehensive mold maintenance plan should be established to regularly clean, lubricate, and inspect the mold, promptly detecting and repairing wear and damage. Additionally, a mold usage record should be maintained to document the number of injection cycles, maintenance history, and failure conditions of the mold, enabling the prediction of mold life and the scheduling of maintenance times.