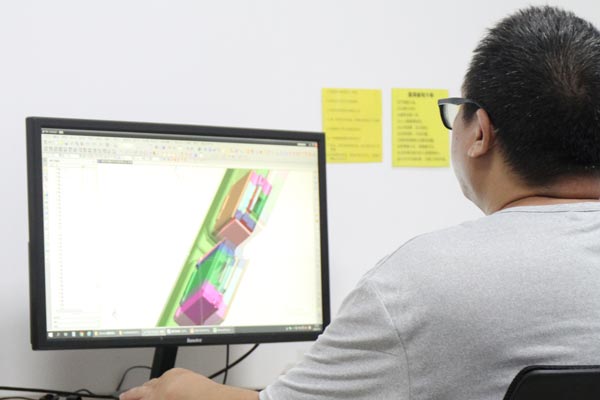

Mold flow analysis tests the success of injection mold design by simulating the injection molding process. For example, it explores how the material you choose flows through the mold, what kind of pressure is required to effectively fill the mold, and how the product’s structural design affects manufacturing.

Multiple Advantages of Mold Flow Analysis

The benefits of mold flow analysis are manifold and far-reaching.

Solving Potential Wall Thickness Challenges

In injection-molded product design, the uniformity and rationality of wall thickness are of utmost importance. Uneven wall thickness can lead to quality issues such as uneven shrinkage and warping deformation, seriously affecting the product’s appearance and performance. Mold flow analysis can predict the material’s flow situation within the mold in advance and accurately identify areas where poor flow may occur due to wall thickness problems. Designers can then make targeted adjustments and optimizations to the wall thickness based on the analysis results, ensuring uniform material flow in the mold and effectively avoiding various quality problems caused by improper wall thickness, thereby improving the overall quality and stability of the product.

Optimizing Gate Location

As the channel through which the plastic melt enters the mold cavity, the location of the gate has a decisive impact on the quality of the finished product. An unreasonable gate location may result in poor plastic flow into the cavity, leading to defects such as insufficient filling, weld lines, and gas marks. Flow analysis can simulate the plastic’s flow path and filling situation under different gate locations. By comparing and analyzing the results, the optimal gate location can be identified. In this way, the plastic can flow into the mold cavity in the most ideal way, ensuring the filling effect and quality of the product, and enabling the finished product to achieve the best state in terms of appearance and performance.

Enhancing Flexibility in Material Selection

In the production process of injection-molded products, material selection is a complex yet crucial link. Different materials have varying physical, chemical, and processing properties, and choosing the right material is essential for the product’s quality and performance. Mold flow analysis can play an important role in the material selection stage. It can simulate the flow and molding situations of multiple different materials under the same mold conditions. Through comparative analysis, designers can have a more intuitive understanding of the characteristics and applicability of various materials, thus flexibly selecting the most suitable material according to the specific requirements of the product and production conditions. This flexibility not only helps improve product quality but also reduces production costs to a certain extent, enhancing the company’s economic benefits.

In conclusion, with its multiple advantages such as solving potential wall thickness challenges, optimizing gate location, and enhancing flexibility in material selection, mold flow analysis undoubtedly provides an effective approach for the high-quality production of injection-molded products, making it an important secret to achieving high-quality injection-molded products.