The plastic molding process holds a pivotal position in the field of plastic product manufacturing. From daily-use plastic cups to precision plastic components in automobiles, this process is indispensable. Today, let’s delve into the principles of plastic injection molding and its five crucial elements.

Principles of Plastic Injection Molding Process

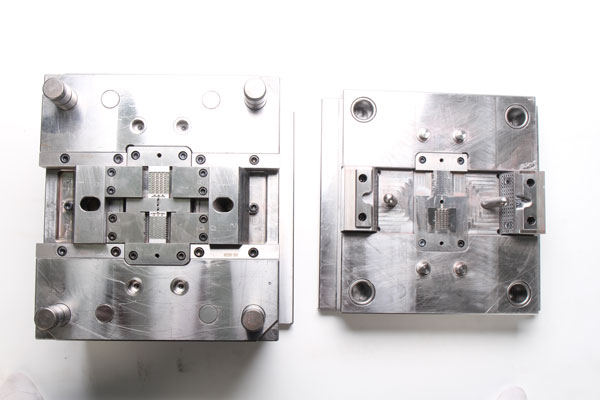

The plastic injection molding process, in simple terms, involves using external heating and the significant heat generated by the rotation of the screw to plasticize the plastic material in the barrel of the injection molding machine into a molten state. Subsequently, this molten material is injected into the cavity of the plastic mold. Under the application of a certain pressure, the molten material gradually forms an object with a specific shape, which, after cooling and solidification, becomes the final product.

Three basic elements are essential for the injection molding process: the injection molding machine, the plastic mold, and the plastic material. The injection molding machine provides the power and precise control for the entire process; the plastic mold determines the final shape and size of the product; and the plastic material serves as the substance of the product. Different materials have distinct characteristics that affect the performance and quality of the product.

Five Key Elements of Injection Molding

Temperature: Precise Control for Product Performance

Temperature plays a critical role in injection molding, encompassing oil temperature, injection temperature, and plastic mold temperature.

- Oil Temperature: For hydraulic machines, heat is generated by the frictional movement of hydraulic oil inside the machine, which is controlled by cooling water. Before starting the machine, it is crucial to ensure that the oil temperature stabilizes at around 45°C. Both excessively high and low oil temperatures can adversely affect pressure transmission, thereby impacting the molding quality of the product.

- Injection Temperature: This refers to the temperature of the barrel. It needs to be precisely set according to the material used as well as the shape and function of the product. Different plastic materials have varying melting points and thermal stabilities. Only by setting an appropriate injection temperature can the plastic material be fully plasticized, laying a solid foundation for the subsequent molding process.

- Plastic Mold Temperature: This is also an extremely importa

- ant parameter that significantly affects the performance of the product. When setting the mold temperature, comprehensive considerations should be given to factors such as the product’s function, structure, material, and molding cycle. An appropriate mold temperature can ensure uniform shrinkage of the product during the molding process, reduce internal stresses, and improve the dimensional accuracy and surface quality of the product.

Speed: Reasonable Settings for Optimizing Molding Efficiency

Reasonable speed settings are vital for improving injection molding efficiency and product quality, including the opening and closing speed of the plastic mold, ejection settings, and injection speed.

- Opening and Closing Speed of the Plastic Mold: Usually, it is set following the principle of slow – fast – slow. This setting mainly considers the machine’s stable operation, the plastic mold’s service life, and the molding cycle’s requirements. In the initial stage of opening or closing the mold, a slower speed is adopted to avoid violent collisions between the molds and protect them. In the middle stage, increasing the speed can improve production efficiency. And when approaching the fully closed or open position, the speed is reduced again to ensure accurate positioning of the molds.

- Ejection Settings: These can be flexibly adjusted according to the structural characteristics of the product. For products with complex structures, a slower ejection speed should be used to prevent deformation or damage during the ejection process. For products with simple structures that require rapid molding, the ejection speed can be appropriately increased to shorten the molding cycle.

- Injection Speed: It needs to be set according to the size and structure of the product. If the product has a complex structure and thin walls, a faster injection speed can be set to ensure that the plastic molten material fills the mold cavity quickly and uniformly. Conversely, for products with simple structures and thick walls, the injection speed can be appropriately reduced to avoid generating excessive internal stresses. In addition, the injection speed should be gradually increased from a slow speed based on the material’s properties to achieve the best molding effect.

Pressure: Scientific Control for Product Quality

Pressure is an indispensable factor in the injection molding process, including injection pressure, holding pressure, and clamping force.

- Injection Pressure: It is set from low to high according to the product size and wall thickness. During the debugging process, other factors such as the fluidity of the plastic material and the structure of the mold also need to be comprehensively considered. An appropriate injection pressure can ensure that the plastic molten material fills the mold cavity smoothly, preventing defects such as short shots and sink marks.

- Holding Pressure: Its main function is to ensure that the product maintains a stable shape and size during the cooling process. The holding pressure and time need to be precisely set according to the product’s structure and shape. During the holding pressure stage, the plastic molten material continues to fill the mold cavity under pressure to compensate for the volume change caused by cooling shrinkage, thereby improving the dimensional accuracy and surface quality of the product.

- Clamping Force: This refers to the compressive force required for mold closing. Some machines allow the clamping force to be adjusted. An appropriate clamping force can ensure that the mold is tightly closed during the injection process, preventing the leakage of plastic molten material and avoiding damage to the mold due to excessive clamping force.

Time: Precise Arrangement for Ensuring Molding Effect

Precise time arrangement is also crucial for the injection molding process, including injection time, cooling time, and dwelling time.

- Injection Time: It is usually set slightly longer than the actual required time. This not only serves as an injection protection but also ensures that the plastic molten material fully fills the mold cavity. Generally, the injection time value should be about 0.2 seconds longer than the actual value. During the setting process, coordination with pressure, speed, and temperature also needs to be considered to achieve the best molding effect.

- Cooling Time: It is generally set according to the size and thickness of the product. However, it should be noted that the melting time should not exceed the cooling time to ensure that the product is fully molded. An appropriate cooling time can enable the product to have sufficient strength and stability after demolding, preventing deformation or cracking due to insufficient cooling.

- Dwelling Time: To ensure the dimensional accuracy of the product after injection molding, the dwelling time allows the gate to fully cool before the molten material flows back under holding pressure. The dwelling time can be set according to the size of the gate. Through a reasonable dwelling time, stress concentration at the gate can be reduced, improving the overall quality of the product.

Position: Precise Setting for Mold and Product Protection

Precise position setting is crucial for protecting the mold and ensuring product quality, including the opening and closing position of the plastic mold, ejection position, and melting position.

- Opening and Closing Position of the Plastic Mold: It can be set according to the opening and closing speed of the mold. The key is to correctly set the starting point of low – pressure protection, that is, the starting point of low pressure should be at an appropriate position that can protect the mold without affecting the molding cycle. The endpoint is the starting point of low – pressure protection. When slowly clamping the mold, the core and cavity will accurately close, ensuring the normal operation of the mold.

- Ejection Position: This position should ensure that the product is fully ejected. When setting, it should be gradually adjusted from low to high. It should be noted that during the installation process of the plastic mold, the ejection position needs to be returned to “0”; otherwise, the mold may be damaged during operation.

- Melting Position: The amount of material required for each injection is calculated based on the product and screw size, and then the corresponding position is set. An accurate melting position can ensure that the amount of plastic required for each injection is precise, preventing defects in the product’s molding quality due to excessive or insufficient material.

The plastic injection molding process is a complex and delicate one. The five key elements of temperature, speed, pressure, time, and position are interrelated and mutually influential. Only by precisely controlling and managing these five elements can high – quality plastic products be produced to meet the needs of different fields. It is hoped that through today’s sharing, everyone can have a deeper understanding of the plastic injection molding process.