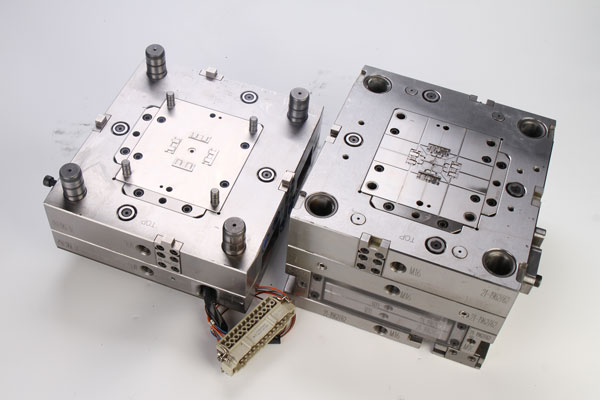

In the precision world of mold manufacturing, molds are like the “magic keys” for mass production of parts. They are production tools that can give raw materials specific shapes and dimensions, enabling the precise creation of parts. However, designing and manufacturing molds involve high costs, so they are typically used only in mass production. Given the crucial role molds play in the production process, accurately manufacturing them is the key to ensuring product quality and production efficiency. Next, let’s delve into two distinct types of molds: multi-cavity molds and family molds.

Multi-cavity Injection Molds: The Perfect Combination of Efficiency and Quality

Multi-cavity injection molds are like versatile “jacks-of-all-trades”. They have two or more cavities on the same part and can produce two or more products in each production cycle. This characteristic significantly shortens the delivery time for each batch, allowing enterprises to complete the delivery of the required quantity of products more quickly.

From the production efficiency perspective, multi-cavity molds are undoubtedly a powerful tool. They notably improve productivity, provide strong support for achieving higher batch production volumes, and can also generate higher yields. Moreover, multi-cavity molds can utilize the cycle time more efficiently. While ensuring the injection effect, they can produce more products using the same mold. Taking Yize Mould as an example, its multi-cavity mold technology is exquisite. It can not only ensure that customers obtain high-quality parts but also strictly maintain precise tolerances and cleverly optimize the cycle time, truly achieving a perfect combination of efficiency and quality.

Family Molds: The “Rapid Pioneer” for Prototype Molds

Family molds are like creative “designers”. They cleverly cut out multiple cavities in the mold, enabling the formation of multiple different products made of the same material in one cycle. Each cavity is usually responsible for forming a different part. Due to the short molding cycle, family molds are highly favored in the field of prototype mold making.

However, family molds are not without their drawbacks. During the filling process, they often face the problem of imbalance. This is because the shapes of various products are usually different, which can easily increase molding defects. Moreover, when multiple parts are taken out of the mold, the subsequent product separation work becomes cumbersome. Since automation is not effective in the separation process, more manual labor is often required, which to some extent increases production costs and labor burdens.

Multi-cavity molds and family molds each have their advantages and disadvantages. When enterprises choose a mold type, they need to comprehensively consider various factors such as production requirements, product quality requirements, and cost control to select the most suitable “production tool” for themselves.