Among numerous thermoplastic materials, PEEK stands out with its outstanding performance and holds a pivotal position in the field of injection molding. It is widely recognized as one of the best-performing thermoplastic materials on the market.

PEEK, as a semi-crystalline thermoplastic, boasts a series of remarkable characteristics. It has excellent wear resistance, enabling it to withstand long-term use and maintain stable performance, significantly extending the service life of products. Its strong chemical resistance allows it to remain unaffected when exposed to acids, alkalis, and various organic solvents, ensuring normal operation of products in different chemical environments. Additionally, it exhibits good hydrolysis resistance, meaning it won’t easily undergo hydrolysis reactions even when in contact with water for extended periods or in humid environments, thus guaranteeing the reliability and stability of products. More impressively, in many application scenarios, PEEK can demonstrate its powerful performance advantages without the need for any additives.

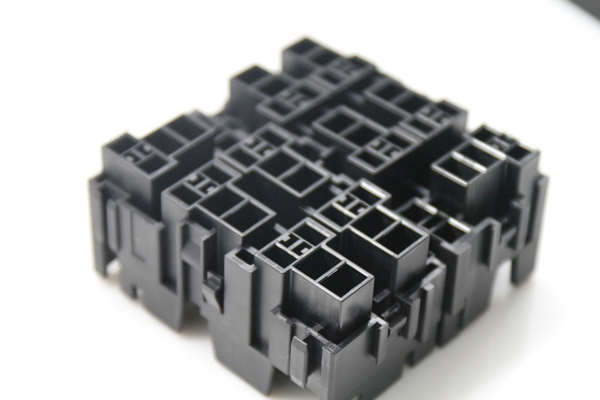

Based on these excellent properties, PEEK injection-molded products have a wide range of applications. In the automotive industry, they are used to manufacture engine peripheral components and transmission system parts, which can withstand high temperatures, high pressures, and harsh chemical environments, providing a solid guarantee for the safe and stable operation of vehicles. In the electronics and electrical sector, PEEK injection-molded products can be used to produce connectors and insulating components. Their excellent insulating properties and high-temperature resistance ensure the reliable operation of electronic equipment in complex environments. In the field of medical machinery, the biocompatibility of PEEK makes it an ideal material for manufacturing artificial joints, implants, and other medical devices, bringing new hope to patients’ health.

However, the PEEK injection molding process is not without challenges and has extremely strict requirements for process parameters. In terms of temperature control, the injection molding temperature is approximately between 320°C and 390°C. Such a high temperature is necessary to make the PEEK material reach a good flow state and smoothly fill the mold cavity. The material drying temperature should be controlled between 160°C and 185°C for 5 to 8 hours. This step aims to remove moisture from the material and prevent defects such as bubbles from forming during the injection molding process due to water evaporation. The mold temperature should be maintained between 140°C and 180°C. An appropriate mold temperature helps ensure the dimensional accuracy and surface quality of the products.

Due to the excessively high molding temperature of PEEK material, it causes relatively severe damage to the screw of the injection molding machine. When setting the screw speed, one must operate with caution and not set it too fast. Otherwise, it will accelerate the wear and tear of the screw, affecting the normal operation of the injection molding machine and the stability of product quality. After the injection molding process is completed, the screw should be promptly cleaned with PE wax to ensure that no PEEK material remains inside the screw. If PEEK material stays in the screw, when the machine is restarted for secondary heating, the residual material will cause more severe damage to the internal structure of the screw, shortening its service life. In addition, when selecting a screw for PEEK material injection molding, it is essential to choose a high-quality alloy screw. This type of screw has better wear resistance and high-temperature resistance, enabling it to better adapt to the harsh conditions of PEEK material injection molding and ensure the smooth progress of the injection molding process and the stable and reliable quality of the products.

PEEK injection molding occupies an important position in industrial production due to the excellent performance of the material itself and its broad application prospects. However, its complex molding process and strict process parameter requirements also pose higher challenges for technology and management during the production process. Only by fully mastering the key technologies and key points of PEEK injection molding can high-quality PEEK injection-molded products be produced to meet the demands of various industries for high-performance materials.