PET plastic is widely used in packaging, electronics, and automotive industries due to its excellent mechanical properties, transparency, and chemical resistance. However, its unique molecular structure (containing ester groups and strong hydrophilicity) imposes stringent requirements on the injection molding process. This article systematically explains the core elements of PET injection molding, from material preprocessing to equipment selection and process parameter control.

1. Plastic Preprocessing: Drying is Critical

The ester groups in PET molecules are prone to hydrolysis with water, leading to molecular weight degradation and material embrittlement. When the moisture content exceeds 0.02%, drying is mandatory:

- Drying Conditions: Use a dehumidifying dryer at 150–160°C for 4–6 hours to ensure moisture content ≤0.005%.

- Drying Verification: Test via the “air jet method”—spray dried pellets into 180°C hot air. If no cracking or bubbling occurs, drying is sufficient.

2. Injection Molding Machine Selection: Precise Matching to Material Properties

PET has a high melting point (~260°C) and a narrow processing window, requiring equipment with precise temperature control and efficient plasticization:

- Screw Design: Use a low-compression ratio (2.0–2.5:1) and long L/D ratio (≥22:1) screw to minimize shear heat and material degradation.

- Shot Size Matching: The single-shot volume should be 60%–80% of the machine’s theoretical capacity to avoid material stagnation and thermal degradation.

3. Mold and Gate Design: Details Determine Product Quality

Mold design must balance insulation, venting, and cooling efficiency:

- Insulation Plate: Install a 12mm-thick insulation plate between the mold and machine to reduce heat loss and ensure mold temperature uniformity (±2°C).

- Venting System: Set 0.01–0.03mm-deep venting slots at parting lines and cores to prevent overheating or burning while avoiding flash.

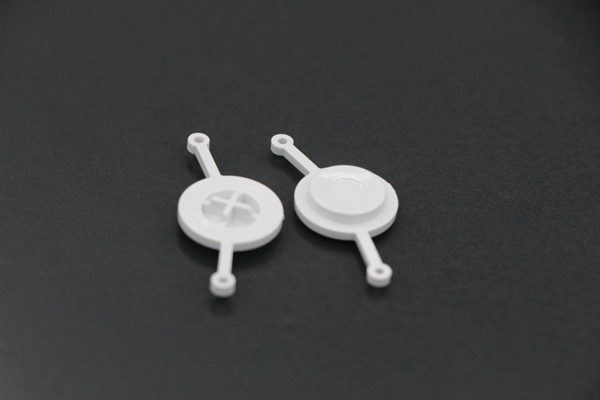

- Gate Type: Prefer pin gates or submarine gates, with runner diameters 20% larger than standard plastics to reduce flow resistance.

4. Process Parameter Control: Balancing Efficiency and Quality

- Melt Temperature:

- Standard PET: 270–295°C;

- Glass-fiber-reinforced PET (GF-PET): 290–315°C.

Excessive temperatures cause degradation; insufficient temperatures reduce flowability.

- Injection Speed:

- Use a “high-speed-low-pressure” two-stage approach: first stage ≥80mm/s to prevent early solidification; second stage 30–50mm/s to reduce shear stress.

- Complete injection within 4 seconds to avoid material stagnation.

- Back Pressure:

- Keep as low as possible (typically ≤10 bar) to prevent excessive shear and perforation risks.

- Packing and Cooling:

- Packing time: 1–3 seconds at 50%–70% of injection pressure to prevent sink marks.

- Cooling time: Adjust based on part thickness (e.g., cooling time ≈ thickness × 1.5 seconds at 70–90°C mold temperature).

5. Shutdown and Material Change: Avoiding Degradation Risks

- Short-term Shutdown (<15 minutes): Maintain barrel temperature and perform “air jet” cycling to prevent carbonization.

- Long-term Shutdown (>15 minutes):

- Clean the barrel with high-viscosity PE and reduce temperature to PE processing range (180–200°C).

- Turn off heaters to prevent localized overheating.

6. Common Defects and Prevention

- Silver Streaking (Blooming):

Cause: Excessive mold or melt temperature leading to material degradation.

Solution: Reduce mold temperature to 60–70°C and optimize cooling water layout. - Poor Transparency:

Cause: Slow cooling speed increasing crystallinity.

Solution: Raise mold temperature to 80–90°C and shorten cooling time.