Damage problems in molds are common among manufacturers with imperfect or unprofessional mold manufacturing processes. Mold damage not only leads to production interruptions and increased costs but may also affect product quality, causing significant losses to enterprises. So, how can we avoid damage problems during plastic mold processing? The following aspects will be elaborated in detail.

1. Reasonable Design of Mold Structure: Laying a Solid Foundation for Quality

The rationality of plastic mold structure design is the primary factor in avoiding processing damage. While meeting the usage requirements of the plastic mold, the structure should be kept as simple as possible. A simple and reasonable structure not only facilitates the molding operation but also reduces complex steps in the processing, lowering the probability of damage caused by structural complexity.

At the same time, the wall thickness of the mold should be as uniform as possible. Uneven wall thickness can generate internal stress within the mold. During subsequent use, this stress will gradually be released, causing deformation of the plastic parts. For example, if a certain part of the mold has excessive wall thickness, its cooling speed will be slower, resulting in a shrinkage difference compared to other thinner parts. This will ultimately lead to issues such as uneven surfaces and dimensional deviations on the plastic parts, affecting product quality. Therefore, the uniformity of wall thickness must be fully considered during the design stage to prevent damage caused by structural problems from the source.

2. Optimizing Heat Treatment Process: Unleashing the Potential of Molds

The heat treatment process plays a crucial role in plastic mold processing. When the structure, material, and usage conditions of the plastic mold are determined, ensuring heat treatment quality and adopting the best heat treatment process are key to fully exploiting the potential of the plastic mold material and extending the mold’s service life.

An appropriate heat treatment process can improve the internal microstructure of the mold material, enhancing its hardness, strength, wear resistance, and toughness, enabling the mold to better withstand various stresses during the molding process. On the contrary, improper heat treatment will not only fail to improve the original defects of the mold material but may further damage its performance. For instance, excessive heating temperature or prolonged holding time may cause overheating or overburning of the mold material, resulting in coarse grain size and reduced mechanical properties. Improper cooling speed may lead to quenching cracks and other defects. Therefore, in the plastic mold processing, great importance must be attached to the heat treatment process. By precisely controlling parameters such as heating temperature, holding time, and cooling speed, the best heat treatment effect can be achieved, providing a guarantee for high-quality mold production.

3. Strict Control of the Manufacturing Process: Ensuring Stable Quality

Strict control of the manufacturing process is an important step in avoiding damage during plastic mold processing. Starting from drawing review, the design drawings of the mold should be carefully checked to ensure that the design meets the requirements and prevent problems caused by design errors in subsequent processing. In the material preparation stage, qualified materials that meet the design requirements should be selected to avoid mold damage due to material quality issues.

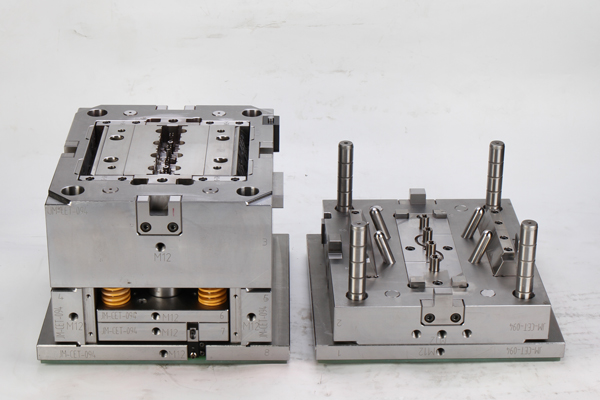

During the processing, whether it is mold frame processing, mold core processing, electrode processing, or mold part processing, operations should be carried out strictly in accordance with the process requirements. Regular maintenance and upkeep of the processing equipment should also be conducted to ensure the accuracy and stability of the equipment. After each processing step is completed, strict quality inspections should be carried out to promptly detect and correct problems, preventing unqualified products from entering the next process.

After passing the inspection, the assembly stage requires ensuring that the assembly accuracy and fit clearances of each part meet the requirements. The mold tryout and mold testing stages are tests of the overall performance of the mold. Through mold testing, problems that may occur in actual production, such as poor molding and difficult ejection, can be discovered, and timely adjustments and repairs can be made. Only by strictly controlling each step can the continuous and stable production of plastic molds be ensured, and damage caused by improper process control can be avoided.

In conclusion, to avoid damage problems during plastic mold processing, it is necessary to take comprehensive measures from multiple aspects, including mold structure design, heat treatment process, and manufacturing process control. Only by striving for excellence in every step can the quality and service life of plastic molds be improved, laying a solid foundation for the stable development of enterprises.