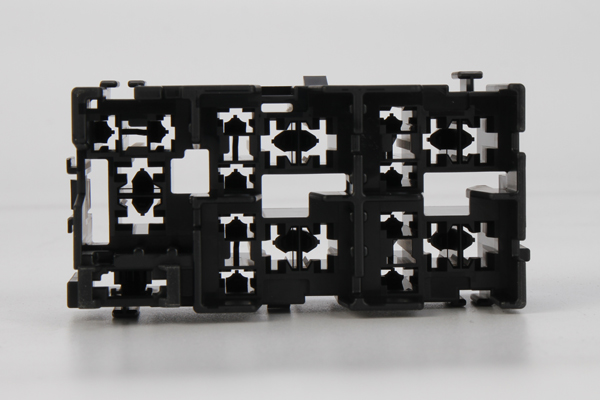

In the field of plastic part injection molding production, appropriate wall thickness design is like the cornerstone of a building, having a profound and crucial impact on the overall quality of products, processing speed, and operating costs. Therefore, in the process of plastic mold manufacturing, the issue of wall thickness must be placed in a highly important position and given careful consideration.

Uniform Wall Thickness: Multiple Advantages Facilitating Production Optimization

Reduced Cooling Resistance and Improved Efficiency

When plastic parts have uniform wall thickness, during the cooling stage, heat can dissipate more smoothly, and the cooling resistance is significantly reduced. This is akin to a wide and flat road where heat can “pass through” without obstruction, enabling the parts to cool rapidly. The increase in cooling speed directly leads to a reduction in injection molding time, thereby enhancing production efficiency and making the entire production process more compact and efficient.

Lightened Product Weight for Convenient Production and Logistics

Uniform wall thickness design helps to reduce the overall weight of products. Lighter products are more convenient to load and unload, reducing the labor intensity of workers and improving loading and unloading efficiency. In terms of management, they take up less space, facilitating classification, storage, and retrieval. In the logistics sector, they can lower transportation costs while enhancing transportation flexibility and safety.

Lowered Overall Costs and Optimized Cost Structure

On the one hand, uniform wall thickness reduces the use of raw materials. By precisely controlling the wall thickness, unnecessary material waste is avoided, directly cutting down on raw material costs. On the other hand, due to the shortened cooling time and improved production efficiency, the turnover time of products is accelerated, reducing the backlog of work-in-progress and enhancing the efficiency of capital utilization, further optimizing the enterprise’s cost structure.

Inappropriate Wall Thickness: Potential Problems Affecting Product Quality

During the cooling stage of plastic part injection molding manufacturing, uniform wall thickness is a key factor in ensuring product quality. If certain areas of a product have thinner wall thickness than others, these weak areas will face greater stress differences during cooling. Just like an unevenly structured building that is prone to problems when subjected to external forces, these thin areas may experience distortion or warping, leading to a decrease in product dimensional accuracy and an inability to meet design requirements. They may also crack, seriously affecting the strength and service life of the product. In extreme cases, collapse may occur, rendering the product completely scrapped. In contrast, appropriate wall thickness design enables the product to experience uniform stress during cooling, effectively reducing the residual stress and shrinkage of the finished product, ensuring product quality and stability.

In conclusion, appropriate wall thickness plays a pivotal role in plastic part injection molding production. Uniform wall thickness offers advantages such as reduced cooling resistance, lighter product weight, and lower costs. Inappropriate wall thickness, on the other hand, can lead to a series of quality issues. Therefore, in the process of plastic mold manufacturing, wall thickness must be scientifically and reasonably designed to ensure efficient, high-quality, and low-cost plastic part injection molding production.