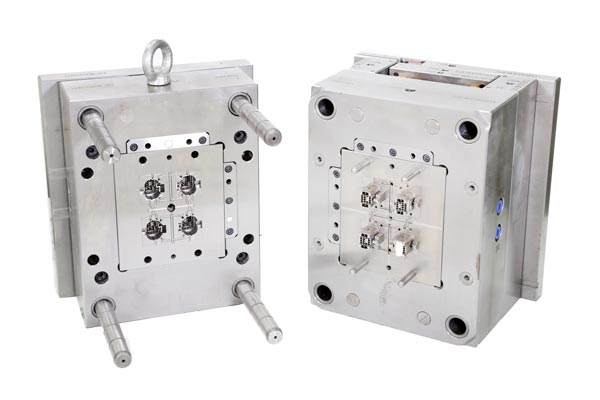

Precision injection mold processing technology plays an indispensable role in the mass production of complex components in modern manufacturing. This process involves thoroughly melting plastic materials through the stirring of an injection molding machine screw at a certain temperature, and then injecting the molten material into the cavity of a precision injection mold under high pressure, which is finally cooled and formed into the desired plastic parts. However, in actual production, leakage issues during precision injection mold processing not only affect product quality but also reduce production efficiency and increase production costs. So, how should we deal with such problems when they arise?

Sealing Area Between the Hot Nozzle and the Separation Plate: Adherence to Operating Standards is Crucial

Leakage in precision injection mold processing often occurs at the sealing area between the hot nozzle and the separation plate. It’s important to note that this situation usually does not stem from poor control system design but rather from the failure to operate strictly according to the main parameters of the molding process. According to general hot runner design standards, there is a rigid edge at the hot nozzle to ensure that the height of the hot nozzle component is less than the actual groove depth on the hot runner plate. In actual production, if operators do not accurately control this parameter, it can easily compromise the sealing performance and lead to leakage. Therefore, strictly adhering to the molding process parameters is the primary prerequisite for preventing leakage at this location.

Equipment Aspect: Inspection and Adjustment are essential.

In addition to operational factors, equipment-related issues can also cause leakage. Insufficient clamping force is a common cause. When the clamping force fails to meet the molding requirements, small gaps may appear in the mold during the injection process, allowing the molten material to leak out. The most direct solution to this problem is to increase the clamping force to ensure that the mold remains tightly closed during injection. Moreover, an excessively fast injection rate can also trigger leakage. A rapid injection rate generates significant impact force on the molten material in the mold cavity. If the flowability of the rubber-molded plastic pellets is poor at this time, the material is likely to overflow. Therefore, reasonably adjusting the injection rate to match the material’s flowability is also a crucial step in resolving leakage issues.

Operational Details: Attention to Detail is Vital

In actual operations, seemingly minor details can also be the culprits behind leakage. For example, if burrs are not promptly removed after demolding, they may hinder the normal closure of the mold during subsequent production, leading to leakage. Additionally, blocked vent holes are another issue that cannot be overlooked. During the injection process, the air in the mold cavity needs to be expelled through the vent holes. If these holes are blocked, the air cannot escape smoothly, creating high pressure inside the mold and causing the molten material to leak. Therefore, operators should develop the good habit of regularly inspecting and cleaning mold burrs and vent holes during daily production to ensure the mold is always in good working condition.

Mold Design: Optimization and Improvement are Imperative

Problems in mold design can also result in leakage. The scientific rationality of the runner design in a precision injection mold directly affects the flow state of the molten material inside the mold. If the runner design is unreasonable, such as being too narrow or having excessive bends, it will increase the flow resistance of the molten material, causing the material to stagnate or flow back during the flow process, which in turn leads to leakage. Furthermore, the lack of vent holes in the cavity is also a common cause of leakage. During injection, if the air in the mold cavity cannot be expelled in a timely manner, high pressure will form inside the mold, forcing the molten material to leak from the mold gaps. Therefore, during the mold design stage, full consideration should be given to the scientific nature of the runner and the venting requirements of the cavity. The runner structure and the positions of the vent holes should be reasonably designed to minimize leakage issues from the source.

In conclusion, leakage issues in precision injection mold processing involve multiple aspects such as operation, equipment, operational details, and mold design. Only by comprehensively and systematically analyzing the causes of the problems and taking targeted handling measures can we effectively solve the leakage issues, improve product quality and production efficiency, and lay a solid foundation for the sustainable development of enterprises.