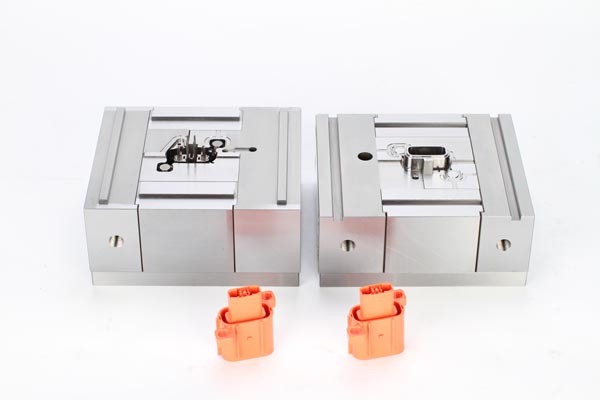

In the design process of precision injection molds, numerous detailed issues cannot be overlooked as they directly impact the mold quality, the performance of injection-molded products, and production efficiency. The following are several key aspects that need to be emphasized during the design of precision injection molds.

Precisely Determine the Mold Opening Direction and Parting Line Position

At the beginning of the design for each injection-molded product, the first task is to clearly define its mold opening direction and parting line position. This step is crucial as it can minimize the use of core-slide mechanisms and effectively eliminate the adverse effects of parting lines on the product’s appearance. After determining the mold opening direction, structures such as reinforcing ribs, snaps, protrusions, etc., on the product should be designed to be as consistent as possible with the mold opening direction. This can prevent core pulling, reduce the occurrence of seam lines, and shorten the molding time.

Reasonably Select the Parting Line

After the mold opening direction is determined, choosing an appropriate parting line is another key step. A suitable parting line can prevent undercuts in the mold opening direction, thereby improving the product’s appearance quality and performance. By carefully planning the position of the parting line, the mold can open and close more smoothly, reducing mold wear and product defects caused by undercuts, and ensuring that the product can be molded in the best possible condition.

Scientifically Set the Draft Angle

Setting an appropriate draft angle is crucial for ensuring product quality. A reasonable draft angle can effectively prevent the product from being damaged at the top during demolding, such as whitening, top deformation, and bursting. Especially when designing deep-cavity structured products, the slope of the outer surface should be as large as possible compared to that of the inner surface. This design can ensure that the mold core does not deviate during the injection molding process, resulting in uniform product wall thickness, guaranteed material strength, and smooth product opening, thus improving production efficiency and product quality.

Reasonably Plan the Product Wall Thickness

Different plastic materials have specific wall thickness ranges, generally between 0.5 – 4mm. When the product wall thickness exceeds 4mm, a series of problems will arise, such as an excessively long cooling time, leading to shrinkage and other defects. In this case, it is necessary to consider optimizing the product structure. In addition, uneven wall thickness is also a significant issue. Uneven wall thickness can not only cause surface shrinkage marks on the product but also lead to air pockets and weld lines, seriously affecting the product’s appearance and performance. Therefore, during the design process, efforts should be made to ensure uniform product wall thickness.

Reasonably Use Reinforcing Ribs

Reasonably using reinforcing ribs is an effective way to increase product rigidity and reduce deformation. By setting reinforcing ribs at appropriate positions on the product, the structural strength and stability of the product can be significantly improved without increasing the overall wall thickness. The design of reinforcing ribs should be reasonably arranged according to the product’s stress conditions and structural characteristics to achieve the best reinforcement effect and ensure that the product can withstand various external forces without deformation or damage during use.

In conclusion, the design of precision injection molds is a complex and meticulous process that requires comprehensive consideration of multiple factors. Only by fully considering and properly addressing the above issues during the design process can high-quality precision injection molds be designed, and high-quality injection-molded products that meet the requirements be produced.