In the context of the booming manufacturing industry, precision injection mold processing holds a pivotal position in numerous fields. It not only contributes to the improvement of product quality but also serves as a key driving force for technological progress in the industry. So, what are the prominent characteristics of precision injection mold processing?

1. Equipment Precision and Personnel Experience: Dual Guarantees for Precision Foundation

Generally, the precision of precision injection mold processing is mainly measured by two key indicators: the precision of injection mold processing equipment and the processing error of the injection mold. As the old saying goes, “A craftsman who wishes to do his work well must first sharpen his tools.” This profound wisdom underscores the importance of equipment precision in precision injection mold processing. To ensure that the processed molds meet high-precision standards, it is imperative to guarantee that the processing equipment itself possesses excellent precision performance.

The guarantee of mold precision, on the other hand, relies heavily on the rich experience of engineering designers and technicians. Their extensive professional knowledge and skilled operational skills, accumulated through long-term practice, are crucial for accurately controlling mold precision. From the initial design of the mold to its subsequent manufacturing, every step embodies their wisdom and efforts, providing solid talent support for high-precision mold processing.

2. Strict Material Selection: Laying a Solid Foundation for Precision Processing

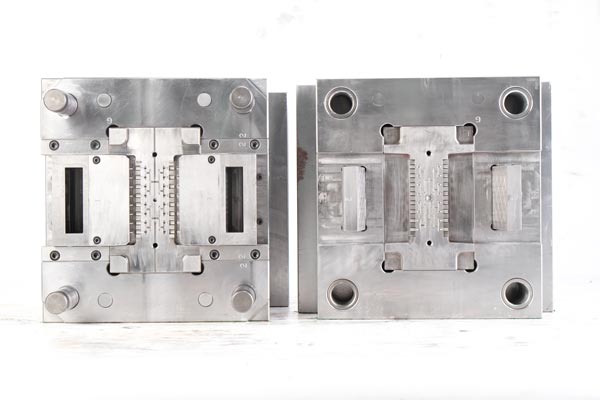

Material selection is the first and most critical step in achieving precision injection mold processing. High-quality mold materials should exhibit excellent rigidity, which is essential for ensuring that the mold remains deformation-free and undamaged under prolonged use and complex processing conditions. At the same time, the dimensional accuracy of the mold cavity must reach an extremely high level to guarantee that the injection-molded products have precise dimensions. The positioning accuracy between mold plates is also of utmost importance as it directly affects the assembly accuracy and overall performance of the mold. Additionally, the surface roughness of the mold should be as low as possible. A smooth surface not only enhances the appearance quality of the products but also reduces friction and wear, thereby extending the service life of the mold.

3. Precise Processing: Pursuing a High Degree of Fit with Ideal Geometric Parameters

Precision injection mold processing imposes extremely stringent requirements on the actual geometric parameters of the part surfaces, including dimensions, shapes, and positions. These actual parameters must closely match the ideal geometric parameters specified in the drawings. When measuring processing precision, the tolerance grade is commonly used as a standard. A smaller tolerance grade value indicates higher processing precision. Processing error, on the other hand, is represented by specific numerical values, with larger values indicating more significant errors. In essence, high processing precision means small processing errors, and vice versa.

4. Equipment Selection: An Inevitable Requirement for Guaranteeing Ideal Geometric Parameters

To ensure that the processed molds fully comply with the ideal geometric parameters specified in the drawings, it is essential to guarantee the precision of the mold processing equipment. Only by using high-precision, high-performance processing equipment can every dimension and shape be precisely controlled during the processing, ensuring that the mold’s various parameters meet the design requirements. Advanced processing equipment not only offers higher processing precision but also improves production efficiency and reduces the scrap rate, creating greater economic benefits for enterprises.

Dongguan Yize Mould Co., Ltd. has been dedicated to the field of precision mold design and manufacturing as well as precision injection molding product production since its establishment in 2007. With years of in-depth accumulation and continuous innovation, the company has developed unique advantages in areas such as automotive connectors, medical product injection molding, cleanroom injection molding, and PFA custom injection molding. We provide a complete range of solutions, from product design, precision mold manufacturing, injection molding and assembly to after-sales service, aiming to offer customers a one-stop, high-quality service experience. We welcome friends from all walks of life to contact us for inquiries. Contact number: +86 13302615729 (same for WeChat and WhatsApp).