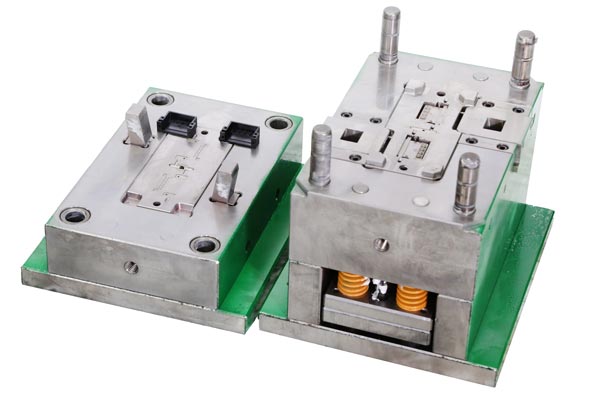

In the field of precision injection mold processing and design, every detail is crucial to the quality and performance of the final product. Among them, the design of mold gates and runners is a key link. If one wants to create a nearly perfect precision injection mold, the design of these two parts cannot be overlooked. Next, this article will provide a detailed introduction to the design standards for mold gates and runners, offering valuable references for industry professionals.

Diverse Choices in Gate Design

Flat Gate: Inclination Design Facilitates Ejection

A flat gate refers to a gate located on the main parting surface of the mold. Based on differences in gate shape, it can be further divided into fan-shaped gates, rectangular gates, and slot-type gates, among others. To facilitate the ejection of the gate from the product, the flat gate can be designed with a certain inclination. This clever design can effectively reduce the resistance during product ejection, preventing issues such as gate residue that could affect the product’s appearance and quality.

Submarine Gate: Ideal for Automated Production, Cautious Material Selection Required

The submarine gate is a commonly used type of gate. During the mold opening process of a precision injection mold, the gate is forcibly detached. This characteristic greatly facilitates the realization of automated production, helping to improve production efficiency and reduce labor costs. However, it should be noted that for brittle plastics, the submarine gate is not an ideal choice. The stress generated during the forced detachment process may cause brittle plastic products to crack or develop other defects, affecting the product acceptance rate.

Pinpoint Gate: Vertical Feed, Special Considerations for Parting Ejection

The pinpoint gate features a unique feeding method where the plastic melt enters vertically from the top surface of the product. During ejection, the product and the gate material need to be removed from different parting surfaces. This design increases the complexity of the mold structure to a certain extent but also has its unique advantages. Nevertheless, due to its feeding and ejection characteristics, brittle plastics are not suitable for use with pinpoint gates. Otherwise, brittle plastic products may be damaged due to uneven stress during vertical feeding and parting ejection.

Gate Location Selection: Adhering to Key Principles

When selecting the gate location for a precision injection mold, a series of important principles must be followed. The primary principle is to ensure the integrity of the precision injection mold during the processing and molding stage, allowing the plastic melt to uniformly and fill the mold cavity and avoiding defects such as short shots. Secondly, it should facilitate venting to prevent problems such as bubbles and scorching caused by trapped gases in the mold cavity, which could affect product quality. Additionally, efforts should be made to minimize the formation of weld lines. Weld lines are linear marks formed when plastic melts converge in the cavity, reducing the mechanical properties and appearance quality of the product. Therefore, rational selection of the gate location is crucial for improving the quality of precision injection mold processing.

Runner Design: Shape and Size Selection Based on Needs

During the design of precision injection mold processing, in addition to carefully designing the gate, the design of the runner cannot be ignored. The shape and size of the runner can be designed into various forms such as trapezoidal, circular, rectangular, or semi-circular according to actual needs. These different runner shapes each have their own characteristics and application ranges. For example, a trapezoidal runner can provide a relatively stable flow state for the plastic melt during the flow process, reducing pressure loss. A circular runner has good symmetry, which is conducive to the uniform flow of the plastic melt. A rectangular runner has a simple structure and is easy to manufacture. A semi-circular runner combines some of the advantages of circular and rectangular runners to a certain extent. Industry professionals can comprehensively consider factors such as specific product requirements, mold structure characteristics, and production efficiency to select the appropriate runner shape and size.

In conclusion, in the design of precision injection mold processing, giving full attention to the design of gates and runners and carefully planning according to the above methods will lay a solid foundation for creating high-quality precision injection molds and help enterprises stand out in the fierce market competition.