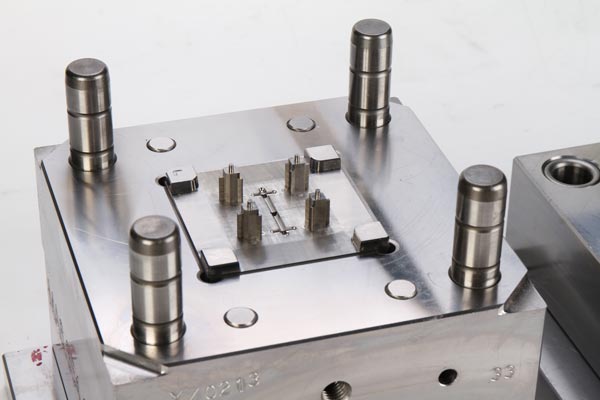

Precision injection mold precisely shaping the form, specifications, and to a large extent, the aesthetic appeal of plastic items. Typically, these molds are crafted from steel and consist of a moving mold and a fixed mold. However, due to their susceptibility to wear and tear, maintenance during the processing of precision injection molds is of paramount importance. The following elaborates on several crucial aspects in detail.

1. Rust Prevention: Shielding Against Moisture Erosion

Preventing rust is the top priority in the maintenance of precision injection mold during processing. Any leakage in the mold’s cooling water system or the accumulation of condensed water can easily lead to mold rusting. Rust not only mars the mold’s surface finish, affecting the appearance quality of products, but over time, it can also damage the mold’s internal structure, thereby impacting its precision and service life. Therefore, it is essential to regularly inspect the mold’s cooling water system to ensure its tightness and promptly remove condensed water, creating a dry, rust-free processing environment for the mold.

2. Collision Protection: Avoiding Accidental Damage

Protecting the mold from collisions is equally crucial. During mold usage, unexpected incidents such as ejector pin breakage or failure to retract fully can easily result in severe mold damage. Once a mold is struck, its precision and structural integrity are significantly compromised, making repairs difficult and costly. To effectively prevent such situations, operators must strictly adhere to standard mold operation procedures, regularly inspect and maintain key components like ejector pins to ensure their proper functioning, and fortify the mold’s safety during use.

3. Burr Removal: Enhancing Mold Quality

Molds are prone to developing burrs during processing due to collisions with water outlet pliers or cutting tools. These burrs not only affect the mold’s fitting precision, leading to product defects, but they can also scratch the mold’s surface during subsequent production, further accelerating mold wear. Therefore, timely removal of mold burrs is a vital step in maintaining mold quality. Professional deburring tools such as sandpaper and files can be used to meticulously polish the mold’s surface, ensuring its smoothness and flatness and laying the foundation for producing high-quality plastic products.

4. Pressure Injury Prevention: Eliminating Residual Hazards

If products remain inside the mold after use and the mold is closed without proper clearance, pressure injuries to the mold are likely to occur. Mold pressure injuries can cause dents and deformations on the mold’s surface, severely impacting its precision and performance. To avoid this, operators must thoroughly inspect the mold’s interior before each closing operation to ensure no product residues are present. Additionally, establishing strict production operation norms and inspection systems and strengthening operator training and management can eliminate the hidden dangers of mold pressure injuries at the source.

The repair costs for precision injection molds during processing are often high. Once a mold is damaged, it not only disrupts production schedules but also inflicts significant financial losses on the company. Therefore, we must attach great importance to the aforementioned points that cause damage to precision injection molds. By implementing scientific and reasonable maintenance measures, we can extend the mold’s service life, reduce repair costs, and provide a solid guarantee for the company’s stable development.