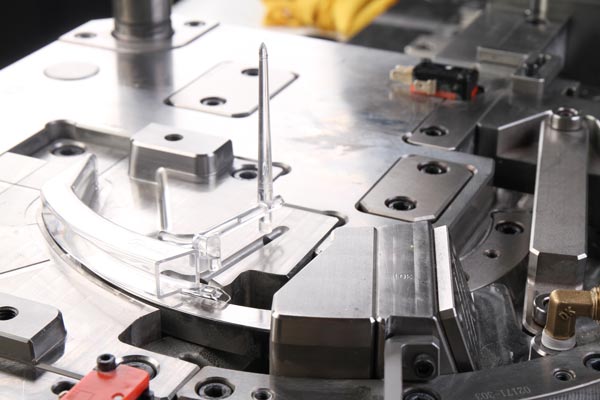

In the processing of precision injection molds, the design and optimization of mold structure are of utmost importance as they directly impact the processing efficiency, molding quality, and service life of the mold. There are numerous and complex factors that influence the processing structure of precision injection molds, which will be elaborated on in detail below.

Cavity Layout: Precise Planning to Balance Multiple Needs

The layout of injection mold cavities is not a random process but requires comprehensive consideration of multiple factors. The geometric characteristics of plastic parts are the primary consideration. For example, for regularly shaped and symmetrical parts, a more regular cavity arrangement can be adopted; while for complex and irregularly shaped parts, the cavity positions need to be carefully designed to ensure uniform plastic filling. The dimensional accuracy requirements also play a crucial role. High-precision parts often require more precise cavity positioning and a more stable processing environment, so the cavity layout should minimize errors caused by improper layout. Batch size is also an important factor. For mass production, in order to improve production efficiency, multi-cavity molds may be used. At this time, it is necessary to reasonably plan the number and arrangement of cavities to fully utilize the mold space and the working capacity of the injection molding machine. Additionally, the difficulty and cost of mold manufacturing are also significant factors. Overly complex cavity layouts may increase the difficulty and cost of mold manufacturing. Therefore, on the premise of meeting production requirements, the cavity structure should be simplified as much as possible to achieve cost-effective processing.

Determination of Parting Surface: Key Positioning to Ensure Multiple Performances

The selection of the parting surface position is a key link in injection mold design, which has a profound impact on mold processing, exhaust, demolding operations, and the surface quality of plastic parts. From the perspective of processing, a reasonable parting surface should facilitate mold manufacturing, reduce processing procedures and difficulty, and improve processing accuracy. In terms of exhaust, the parting surface can serve as one of the main exhaust channels. Its position and structural design should be able to timely and effectively exhaust the gas in the mold cavity to avoid defects such as bubbles and scorching in the parts caused by gas retention. For demolding operations, the selection of the parting surface should ensure that the parts can be smoothly demolded without getting stuck in the mold due to improper parting surface design. At the same time, the position of the parting surface will also directly affect the surface quality of plastic parts. It should avoid leaving parting line marks on the appearance surface of the parts as much as possible to ensure their aesthetics.

System Planning: Gating and Exhaust Systems, Collaborating to Ensure Molding

The design of the gating system and the exhaust system is an important part of the processing structure of precision injection molds. The gating system includes the sprue, runners, and gates. The determination of their shapes, positions, and sizes needs to comprehensively consider the flow characteristics of the plastic, the shape and size of the parts, and production efficiency. A reasonable gating system design can ensure uniform plastic flow in the cavity and avoid defects such as insufficient filling and weld lines. For example, for large parts, a multi-gate design may be required to shorten the plastic flow distance and improve the filling effect. The exhaust system is mainly responsible for exhausting the gas in the mold cavity. Its exhaust method, the position and size of the exhaust ports should be reasonably selected according to the mold structure and the plastic filling situation. If the exhaust is not smooth, it will lead to bubbles inside the parts, affecting their mechanical properties and appearance quality.

Demolding and Core-Pulling: Ingenious Design to Achieve Smooth Demolding

The selection of demolding mechanisms such as ejector pins, ejector sleeves, push plates, and combined ejectors, as well as the determination of undercut treatment methods and core-pulling methods, are the keys to ensuring smooth demolding of parts. Different part shapes and structures require different demolding methods. For example, for parts with a simple shape and small demolding force, ejector pins or ejector sleeves can be used for demolding; while for parts with complex shapes, side recesses, or side holes, core-pulling mechanisms are required for demolding. The selection of undercut treatment methods should also be based on the specific situation of the parts. Reasonable undercut treatment can avoid damaging the parts during the demolding process. At the same time, the determination of the core-pulling method should take into account the stability, reliability, and efficiency of core-pulling to ensure that the core-pulling process proceeds smoothly without affecting the part quality and production efficiency.

Temperature Control System: Precise Regulation to Optimize the Molding Environment

The selection of cooling methods and heating methods, as well as the determination of the shapes and positions of heating and cooling channels and the installation positions of heating elements, are crucial for controlling the temperature distribution of the mold and optimizing the molding environment. The design of the cooling system should be able to cool the mold quickly and uniformly, enabling the parts to solidify rapidly after molding and improving production efficiency. At the same time, the shapes and positions of the cooling channels should be reasonably arranged to avoid uneven cooling, which may lead to defects such as uneven shrinkage and warping in the parts. The selection of the heating method should be determined according to the characteristics of the plastic and the molding process requirements. For some plastics that require heating for molding, such as thermosetting plastics, appropriate heating methods should be adopted to ensure the fluidity and molding quality of the plastic. The installation positions of heating elements should ensure uniform heating of the mold and avoid local overheating or underheating.

Part Design: Based on Standards to Ensure Reasonable Structure

Determining the thickness and shape, structural form, and the positions of all connections and positioning of mold parts based on injection mold materials, strength calculations, or empirical data is an important step to ensure the rationality and reliability of the mold structure. The selection of mold materials should take into account performance indicators such as strength, hardness, wear resistance, and corrosion resistance to meet the requirements of the mold during long-term use. Strength calculations can be carried out according to the stress situation and working environment of the mold. By calculating, the reasonable thickness and shape of mold parts can be determined to ensure that the mold will not deform or be damaged during the working process. Empirical data is precious wealth accumulated during long-term mold design and manufacturing. It can be referred to optimize the design of mold parts and improve design efficiency and quality. At the same time, the determination of connection and positioning positions should be accurate to ensure that the mold parts can fit closely with each other and ensure the assembly accuracy and operational stability of the mold.

Structural Form: Primary and Secondary Distinction to Build a Stable Framework

The determination of the structural forms of the main molding parts and structural parts is the basis of the overall structural design of the mold. The main molding parts are the main parts for molding the parts, and their structural forms should be designed according to the shape and size requirements of the parts to ensure accurate molding of parts that meet the requirements. Structural parts play roles such as support, connection, and positioning, and their structural forms should be able to ensure the overall strength and stability of the mold. The main molding parts and structural parts should cooperate to form a stable framework structure, providing a guarantee for the normal operation of the mold.

Strength Calculation: Scientific Calculation to Ensure Working Dimensions

Considering the strength of each part of the injection mold and calculating the working dimensions of mold parts are important links to ensure that the mold can withstand various loads during use and ensure the quality of parts. The mold is subject to multiple loads such as injection pressure, mold opening force, and demolding force during the working process, so strength calculations are required for each part of the mold to determine whether it can meet the working requirements. Through strength calculations, the reasonable dimensions and shapes of mold parts can be reasonably determined to avoid mold damage or part quality degradation due to insufficient strength. At the same time, the calculation of working dimensions should also take into account factors such as mold manufacturing errors and the shrinkage rate of plastics to ensure that the dimensional accuracy of the parts meets the design requirements.

In conclusion, the factors influencing the processing structure of precision injection molds involve multiple aspects such as cavity layout, parting surface determination, system planning, demolding and core-pulling, temperature control system, part design, structural form, and strength calculation. Only by comprehensively considering these factors and conducting scientific and reasonable design and optimization can high-quality and high-efficiency precision injection molds be manufactured to meet the needs of modern industrial production.