In the field of precision plastic mold manufacturing, the texturing process holds a crucial position. It not only enhances the aesthetic appeal and surface performance of plastic products molded by the molds but also enjoys widespread application due to its unique advantages. Below is a detailed introduction to various aspects of the texturing process for precision plastic molds.

I. Overview of the Texturing Process

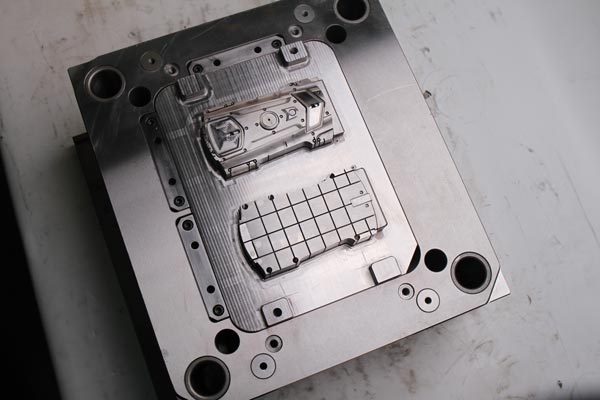

Texturing is a common surface treatment process for precision plastic molds, significantly impacting the appearance and surface strength of plastic products. It is also known as mold embossing, mold etching, and mold engraving. Owing to its relatively low cost, diverse effects, and fast processing speed, this process is widely used in precision plastic mold manufacturing.

II. Basic Principles of the Texturing Process

The texturing process for precision plastic molds mainly relies on chemical reactions between organic chemicals (such as hydrochloric acid and nitric acid) and the stainless steel of the mold. By precisely controlling the reaction process, a variety of texture effects can be achieved on the mold surface to meet different design requirements.

III. Objectives of the Texturing Process

- Enhance Appearance Texture: After texturing, the appearance texture of plastic parts is significantly improved. The originally smooth and uniform surface can exhibit various textures, such as fine, rough, regular, or irregular patterns, adding a sense of quality and three-dimensionality to the product and enhancing its overall aesthetic appeal.

- Achieve Diverse Designs: The texturing process offers more possibilities for the design of plastic parts. It enables plastic parts to showcase a wide range of or completely new design styles, meeting the personalized appearance requirements of different customers and enhancing the product’s competitiveness in the market.

IV. Production Process of the Texturing Process

- Mold Preparation: This is the first step in the texturing process. The mold needs to be thoroughly inspected and cleaned to ensure there are no impurities, oil stains, or damages on its surface. Additionally, necessary pre-treatment processes such as grinding and polishing are carried out according to design requirements to ensure the uniformity and consistency of the texturing effect.

- Film Exposure: The designed texture pattern is made into a film. The quality of the film directly affects the final texturing effect, so it is essential to ensure the clarity and accuracy of the pattern. During the production process, strict adherence to design requirements is necessary to avoid pattern distortion or blurring.

- Film Application: The produced film is accurately pasted onto the corresponding position on the mold surface. This step requires high skills and experience from the operator to ensure tight adhesion between the film and the mold surface without air bubbles or wrinkles, guaranteeing uniform exposure results.

- Exposure: The mold with the applied film is exposed to ultraviolet light. During exposure, the ultraviolet light passes through the transparent parts of the film, causing a chemical reaction in the photosensitive material on the mold surface. The exposure time and intensity need to be precisely controlled according to the properties of the mold material, photosensitive material, and design requirements to achieve the desired texturing effect.

- Etching: After exposure, the mold is placed in a chemical etching solution for etching treatment. The chemical etching solution selectively etches the mold surface based on the differences between the exposed and unexposed areas, forming the required texture pattern. The etching time and depth are key parameters that need to be strictly controlled to avoid over-etching or under-etching.

- Cleaning: After etching, the mold needs to be thoroughly cleaned to remove residual chemical etching solution and impurities from its surface. Appropriate cleaning agents and methods should be used during the cleaning process to ensure the mold surface is clean and free of contamination while avoiding damage to the mold.

- Post-Treatment: The cleaned mold may require some post-treatment processes, such as rust prevention treatment and polishing treatment. Rust prevention treatment can prevent the mold from rusting during storage and use, extending its service life. Polishing treatment can further improve the surface smoothness of the mold, making the texturing effect clearer and more aesthetically pleasing.

V. Characteristics of the Texturing Process

- Low Cost: Compared with other mold surface treatment processes, the texturing process for precision plastic molds has relatively low costs. The etching cost for a set of molds usually ranges from over a thousand yuan to within ten thousand yuan, depending on the complexity of the mold and the requirements for the texture effect. This cost advantage makes the texturing process widely used in small and medium-sized enterprises.

- High Pass Rate: After texturing treatment, the pass rate of injection-molded parts can be significantly improved during the injection molding process. Texturing can improve the demolding performance of the mold surface, reduce the adhesion between plastic products and the mold, and lower the probability of product defects such as burrs and scratches, thereby improving product quality and production efficiency.

- Fast Processing Speed: The processing cycle of the texturing process for precision plastic molds is relatively short. Generally, the entire manufacturing process can be completed in about three days. For enterprises, this can shorten the product production cycle, quickly respond to market demands, and enhance their competitiveness.

- Diverse Effects: The texturing process can achieve a wide variety of texture effects to meet the design requirements of different products. Whether it is wood grain, leather grain, matte grain, or other special textures, they can all be presented on the mold surface through the texturing process, adding unique charm and value to the products.

The texturing process for precision plastic molds plays a vital role in precision plastic mold manufacturing with its unique principles, clear objectives, standardized production process, and significant process characteristics. As the market’s requirements for the appearance and performance of products continue to increase, the texturing process will also continuously develop and improve, bringing more innovations and breakthroughs to the plastic products industry.