The issue of deformation in plastic mold products has long been a major headache for mold manufacturers, seriously affecting product quality and production efficiency. Throughout the complex process of plastic mold processing, the risk of deformation lurks at every turn, with potential “pitfalls” hidden in each link. Next, we will conduct a detailed analysis of the key links in plastic mold processing that are prone to deformation and provide practical prevention strategies.

I. Selection and Determination of the Shrinkage Rate of Plastic Materials

Even for the same type of plastic material, its shrinkage rate can vary significantly under different molding conditions. During plastic mold molding, the ideal situation is to have a minimal shrinkage variation rate and for the estimated shrinkage rate to closely match the actual one. However, in reality, it is extremely difficult to achieve this precision.

As a result, mold modifications are often required after trial molding. For example, when producing a high-precision electronic plastic housing, inaccurate estimation of the plastic material’s shrinkage rate led to significant dimensional deviations in the first batch of products, failing to meet customer requirements. After multiple trial moldings and mold adjustments, the product dimensions finally met the standards. Therefore, accurately grasping the shrinkage rate of plastic materials is the first crucial step in preventing mold deformation.

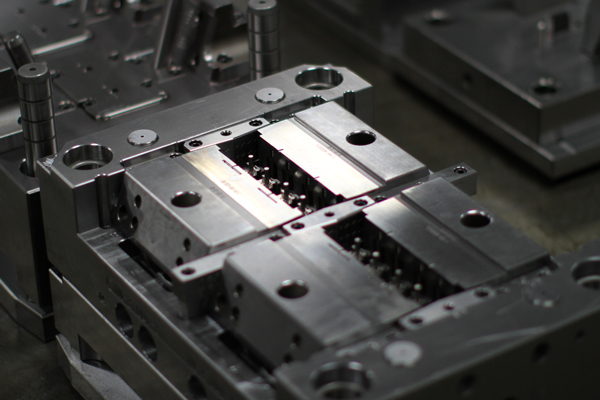

II. Precision Control of Plastic Mold Dimensions

The determination of the dimensional accuracy of plastic molds should be closely based on the product drawings, taking into full consideration the entire process of mold design, fabrication, and injection molding. Ensuring that the actual dimensions of the plastic mold strictly fall within the dimensional tolerance range specified in the drawings is the core factor in guaranteeing the accuracy of the final products.

Even a slight deviation in mold dimensional accuracy can trigger a chain reaction, causing deformation or dimensional discrepancies in the final products. Take the plastic interior parts of automobiles as an example. Their mold dimensional accuracy requirements are extremely high. Even a tiny error can lead to assembly problems, affecting the overall interior quality of the vehicle. Therefore, high-precision measuring tools and advanced processing techniques should be employed in every link of mold design, fabrication, and processing to strictly control dimensional accuracy.

III. Deformation Risks during the Injection Molding Process

The main cause of deformation in plastic molds during the injection molding process is uneven shrinkage, which generates internal stresses within the mold and ultimately leads to product deformation. This type of deformation is particularly common when producing large, thin-walled, or structurally complex plastic products.

For instance, when manufacturing large plastic storage boxes, uneven cooling rates of the plastic during injection molding result in different shrinkage degrees in various parts, causing the storage boxes to twist and deform. To reduce such deformation, it is necessary to optimize the injection molding process parameters, such as injection speed, holding pressure, and cooling time, to ensure uniform cooling and shrinkage of the plastic within the mold and minimize the generation of internal stresses.

IV. Deformation Hazards during the Demolding of Plastic Products

When the shrinkage rate of the plastic material is relatively low and the molding pressure is high, plastic products tend to adhere tightly to the mold cavity, making demolding extremely difficult. If the demolding method is improper at this time, it is very likely to cause deformation of the plastic products during the demolding process.

For example, when producing some small precision plastic parts, improper control of the demolding force resulted in scratches and deformation on the part surfaces, affecting the appearance and performance of the products. Therefore, during the mold design stage, full consideration should be given to the convenience and safety of demolding. Reasonable demolding structures and methods, such as designing appropriate draft angles and ejection mechanisms, should be adopted to ensure smooth demolding of plastic products without deformation.

The deformation problem in plastic mold processing is complex, but by thoroughly understanding the risk points in each link and adopting targeted prevention measures, we can effectively reduce the probability of deformation and improve the quality and production efficiency of plastic mold products. We hope that the above content can provide useful references for mold manufacturers and help them achieve better results in the field of mold processing!