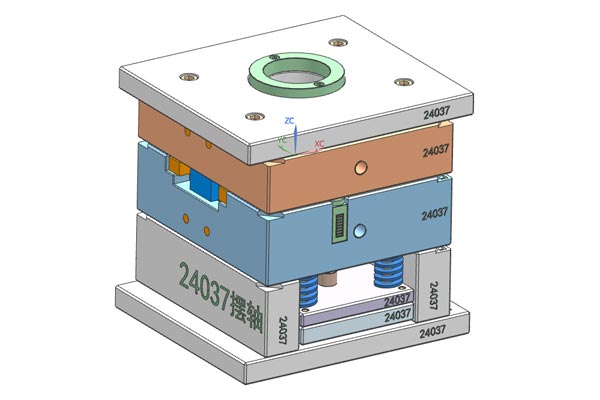

Dongguan Yize Mould Co., Ltd., established in 2007, currently employs over 100 people and is located in Chang’an Town, Dongguan City, the company offers integrated solutions encompassing MIM (Metal Injection Molding) moulds, MIM metal powder injection molding, cleanroom injection molding, and liquid silicone rubber injection molding.

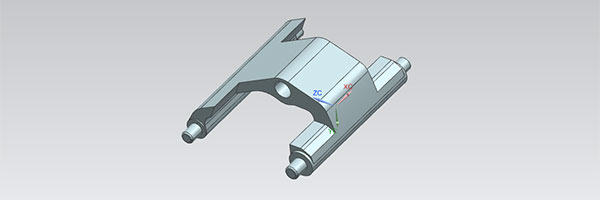

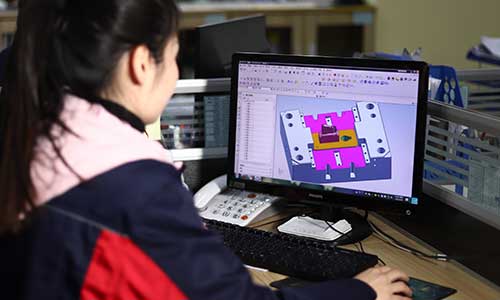

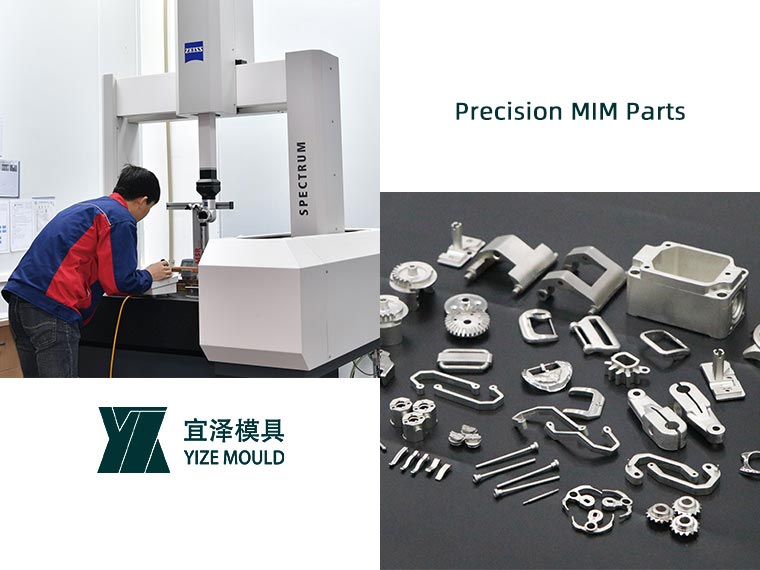

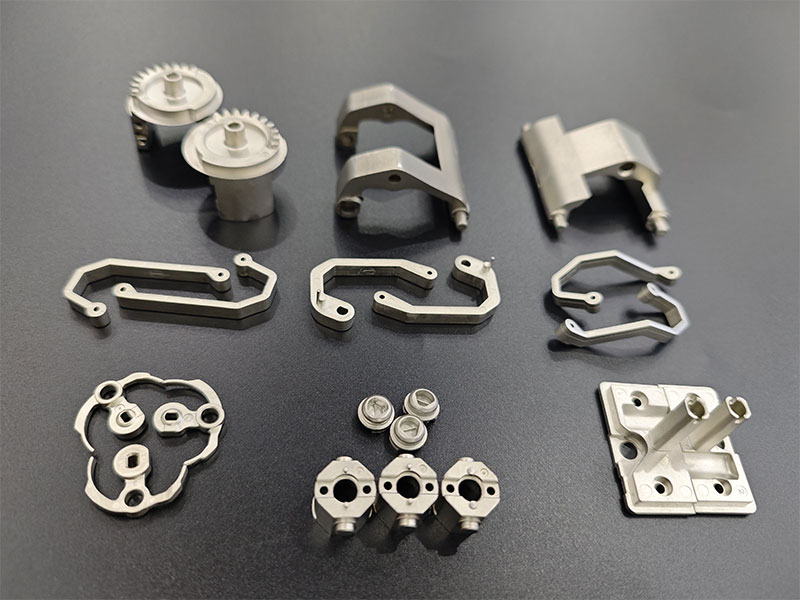

Leveraging its advantages in independent precision mould development, Yize deeply integrates MIM mould design and manufacturing, metal powder injection molding, debinding, sintering, and post-processing. The company specializes in the large-scale production of complex-structured, small high-precision metal components. MIM parts can achieve a density of 96% to 99%, with mechanical properties approaching or even matching those of forged parts, while also offering high material utilization and minimal waste. Compared to traditional CNC machining or precision casting, Yize significantly reduces the comprehensive cost per unit in medium to large-scale production, balancing performance and cost-effectiveness.

Through continuous technological innovation and stable mass production capabilities, Yize Mould has gradually grown into a trusted manufacturer of MIM metal powder injection solutions, widely serving industries such as medical devices, electronic communications, automotive, and precision machinery.