Dongguan Yize Mould Co., Ltd. was established on January 1, 2006, with 170 employees, and is located in Chang’an Town, Dongguan City, known as the “Key Town of China’s Mould Industry”.

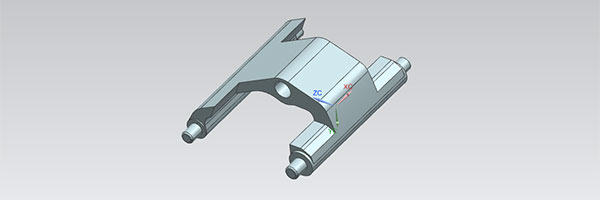

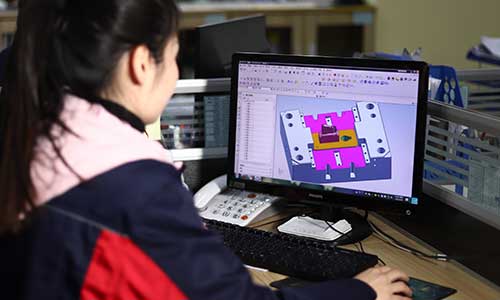

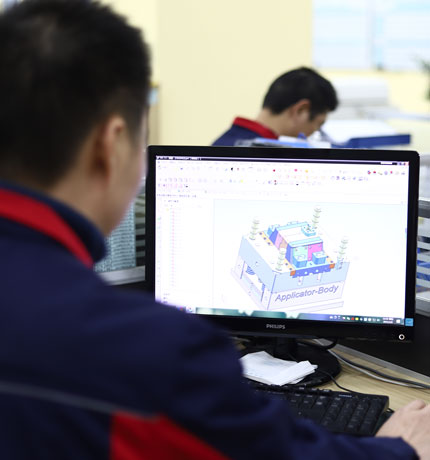

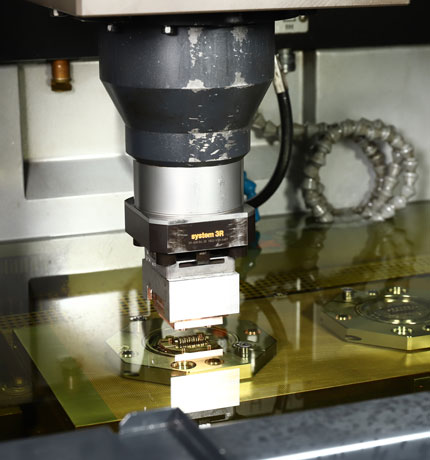

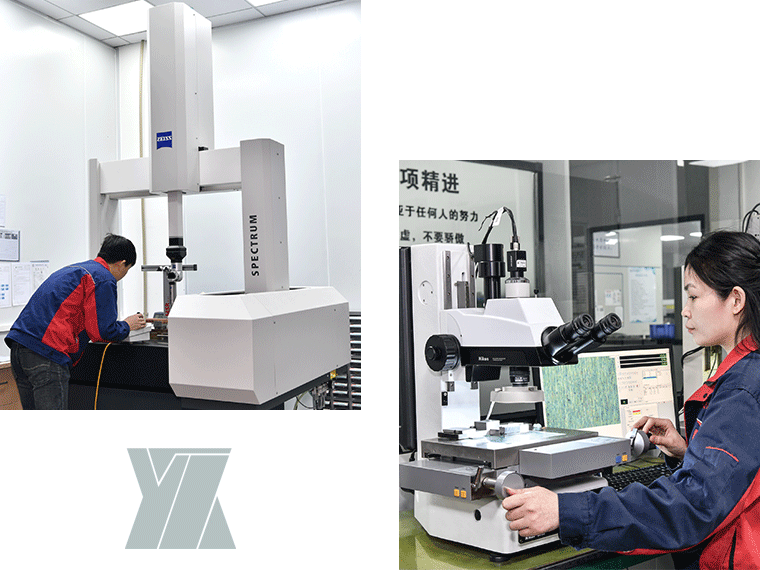

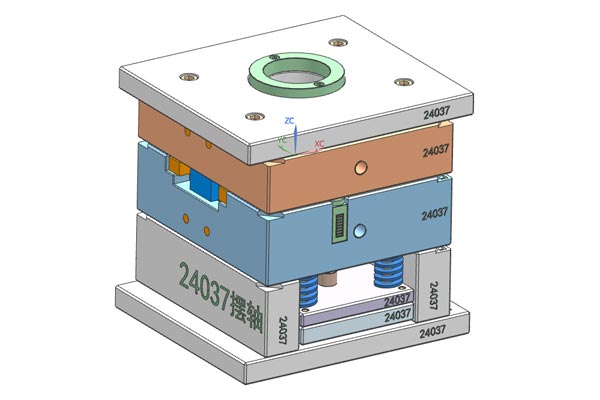

Since its establishment, Yize has always focused on technology as its core, specializing in the OEM sector of precision molds, precision metal and plastic components. The company has gradually expanded its business scope to encompass comprehensive solutions for precision mold components, precision injection molds, injection molding of special materials, cleanroom injection molding, silicone injection molding, and precision structural parts via MIM (Metal Injection Molding) metal powder injection molding.

Yize Mould continuously innovates and develops, becoming a leader in the field of high-end precision mold manufacturing and related products, and is a trustworthy manufacturer of metal injection molding.