In the precision injection molding industry, the quality of mold processing molded parts is like the foundation of a building, crucial for the performance and reliability of the entire product. So, what factors actually affect the quality of precision injection mold processing molded parts? In fact, factors such as the processing accuracy of the injection mold, the parameters of the injection molding process, the selection of raw materials, the performance of the machine, and the packaging of the product are all interconnected like precision gears. Any oversight in any of these links can lead to significant quality issues in the products. Next, let’s delve into these key factors influencing the quality of precision injection mold processing molded parts.

1. Performance of the Injection Molding Machine: The Cornerstone of Quality and Efficiency

The quality of precision injection mold processing molded parts largely depends on the precision and sensitivity of the molding machine, which serve as the pillars supporting the entire production process. There are significant performance differences between new and old machines, hydraulic and electric machines, and domestic and imported machines. A poorly performing machine is like an old, frequently malfunctioning car, constantly emitting alarms, breaking down, and requiring repairs. This inevitably causes significant fluctuations in process stability, resulting in inconsistent product quality.

Therefore, when selecting a molding machine for production, it is essential to choose based on the precision requirements of the product. For products with low precision requirements, a general-brand molding machine can meet production needs, ensuring a certain level of production efficiency while controlling costs. However, for the production of high-precision plastic parts, it is imperative to use a high-performance machine. These high-performance machines, like skilled craftsmen, can precisely control every production step, ensuring stable and reliable product quality while improving production efficiency and creating greater value for the enterprise.

2. Selection of Raw Materials: The Key to Determining Intrinsic Quality

Raw materials are the material foundation of precision injection mold processing molded parts, and their quality directly affects the performance of the final product. During the processing, each material has unique physical and mechanical properties as well as process properties, and different proportions of additives can also alter the material’s characteristics. This is similar to how different ingredients and seasonings in cooking can create vastly different flavors.

Therefore, before production and processing, it is crucial to have a thorough understanding of the molding process properties of each material. Only by fully understanding the material properties can one select the appropriate raw materials according to the product design requirements and production process, and accurately control the various parameters during processing to ensure that the quality of precision injection mold processing molded parts meets standards. Otherwise, if there is a lack of understanding of material properties and blind processing is carried out, it is likely to lead to various quality issues in the products, such as cracking, deformation, and uneven color.

3. Precision Injection Mold Processing: Details Determine Success or Failure

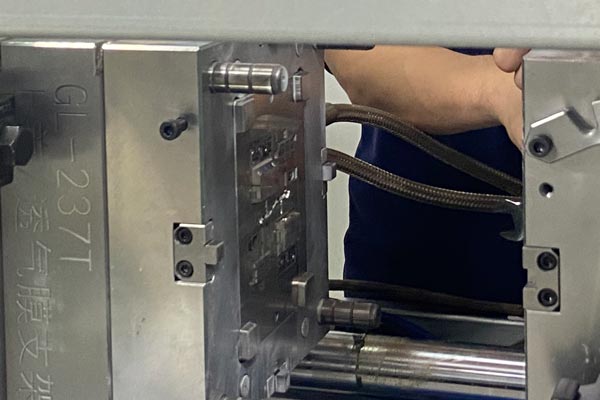

The mold is the core tool in precision injection mold processing, and its quality directly relates to the precision and quality of the molded parts. During the mold trial process, it is necessary to conduct a comprehensive and detailed inspection of the mold, just as a rigorous doctor diagnoses a patient’s condition. Not only should existing problems with the mold be identified, such as whether the structure is reasonable and whether the manufacturing precision meets standards, but potential hazards should also be predicted, such as whether the steel selection is appropriate and whether the cycle time of the plastic parts is reasonable.

Once problems or potential hazards are identified, a repair plan should be promptly formulated to repair and optimize the mold. This is like treating a disease in its early stages, which can prevent the condition from worsening and reduce the difficulties and losses associated with repairing the mold during later production. If mold problems are ignored and repairs are only carried out during the production process, it will not only affect production progress but may also lead to unstable product quality and increased production costs.

4. Injection Molding Process Conditions: The Art of Fine Adjustment

The five key elements of injection molding—pressure, speed, position, time, and temperature—are like notes on a musical staff, working together and complementing each other to compose a melody of high-quality products. The process of machine adjustment is about finding the optimal balance among these five elements. Only by adjusting them to appropriate values can qualified products be produced. This requires operators to have rich experience and superb skills, like a highly skilled conductor who can precisely control every aspect.

However, many defects in plastic parts often result from unreasonable settings of these five elements. For example, excessive pressure may cause problems such as flash and overflow in the product; excessive speed may lead to defects such as bubbles and shrinkage cavities inside the product; and temperatures that are too high or too low can affect the molding quality and performance of the product. Therefore, during the machine adjustment process, it is necessary to carefully and patiently debug and optimize to ensure that each parameter meets production requirements and thus produce high-quality precision injection mold processing molded parts.

The quality of precision injection mold processing molded parts is influenced by a combination of multiple factors. Only by comprehensively and meticulously controlling factors such as the performance of the injection molding machine, the selection of raw materials, precision injection mold processing, and injection molding process conditions can high-quality and high-performance precision injection products be produced, enabling enterprises to stand out in the fierce market competition.