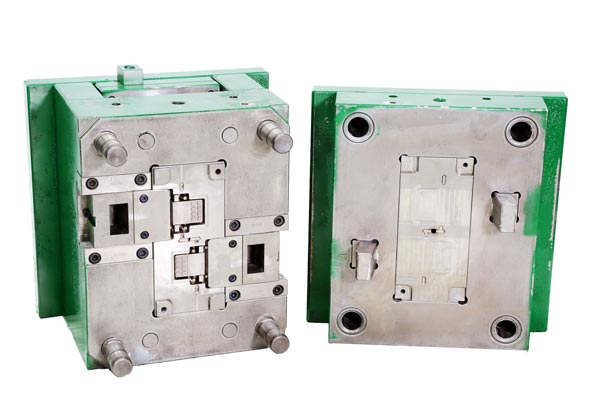

The precision plastic mold sandblasting process holds a pivotal position in the field of mold manufacturing and treatment, with its fundamental principles and practical significance profoundly influencing the quality, performance, and subsequent usage effects of molds. The following provides a detailed exposition on these two core aspects.

I. Fundamental Principles of the Precision Plastic Mold Sandblasting Process

In essence, the precision plastic mold sandblasting process is a procedure that employs the impact of high-speed sand flows to clean and passivate conventional surfaces. Specifically, this process utilizes compressed air as the driving force to generate a high-speed jet stream. This stream propels abrasive materials (including copper ore sand, quartz sand, diamond sand, iron sand, and Hainan sand) at extremely high speeds onto the surface of the workpiece to be treated.

During this process, the outer surface morphology or shape of the precision plastic mold workpiece undergoes significant changes. Due to the continuous impact and cutting action of the abrasive materials on the workpiece surface, the surface achieves a certain level of cleanliness and exhibits varying degrees of surface roughness. These alterations in the surface physical properties have multiple positive impacts: they effectively enhance the fatigue resistance of the workpiece, strengthen the adhesion between the workpiece and the coating, extend the service life of the coating, and facilitate the leveling and decoration of the coating, enabling the mold to better meet various performance and appearance requirements in subsequent use.

II. Practical Significance of the Precision Plastic Mold Sandblasting Process

(1) Direct Impact on Coating Performance

The quality of pre-treatment in the sandblasting process has a decisive influence on several properties of the coating. It directly affects the adhesion of the coating, ensuring that the coating adheres more tightly to the mold surface and is less prone to detachment. It also impacts the appearance of the coating, resulting in a more uniform and aesthetically pleasing coating on the sandblasted mold surface. Furthermore, it significantly influences the coating’s resistance to moisture and corrosion. By optimizing the surface condition, the coating’s ability to withstand erosion from the external environment is enhanced, thereby ensuring the long-term stable use of the mold under complex working conditions.

(2) Prevention of Rust Propagation Under the Coating

If the mold surface is not properly treated, rust issues can continue to propagate under the coating, ultimately leading to large-scale shedding of the coating and seriously affecting the service life and performance of the mold. In contrast, a carefully sandblasted surface, when compared to a mold workpiece that has undergone only simple cleaning, shows a significant difference in coating service life. Through exposure testing for coating life comparison, it has been found that the coating service life of the former can be 4 – 5 times longer than that of the latter. This fully demonstrates the irreplaceable role of the sandblasting process in preventing rust propagation and ensuring the long-term effectiveness of the coating.

(3) Widely Recognized Surface Cleaning Method

Among the numerous methods for cleaning the surface of precision plastic molds, the sandblasting process is one of the most widely accepted approaches. Other common methods include organic solvent cleaning, pickling and passivation, manual tool cleaning, and power tool cleaning. However, the sandblasting process stands out due to its unique advantages. It can comprehensively and thoroughly clean the mold surface and effectively improve the surface properties, providing an ideal foundation for subsequent coating treatments.

In conclusion, the precision plastic mold sandblasting process, with its unique fundamental principles, plays a crucial role in improving the surface properties of molds. Meanwhile, its important practical significance permeates the entire process of mold manufacturing, use, and maintenance, providing a strong guarantee for enhancing mold quality and extending service life.