In the field of injection mold production, precise control of cooling temperature is of paramount importance for product quality, mold service life, and production efficiency. Traditional methods of temperature control in injection molds primarily rely on subjective human experience, with operators often using mold release agents to lower the mold temperature. However, this conventional approach is plagued with numerous serious issues.

On one hand, subjective human-based operations struggle to ensure accurate temperature control, severely challenging the stability of product quality and potentially increasing the defect rate. Simultaneously, improper temperature control can accelerate mold wear, shortening the mold’s service life and increasing equipment costs for enterprises. On the other hand, this operational model is fraught with drawbacks, requiring substantial human resources for frequent monitoring and adjustments, leading to a significant rise in labor costs. Moreover, manual operations are inefficient and fail to meet the demands of large-scale, high-efficiency production. Temperature fluctuations are also difficult to effectively manage, further impacting product quality.

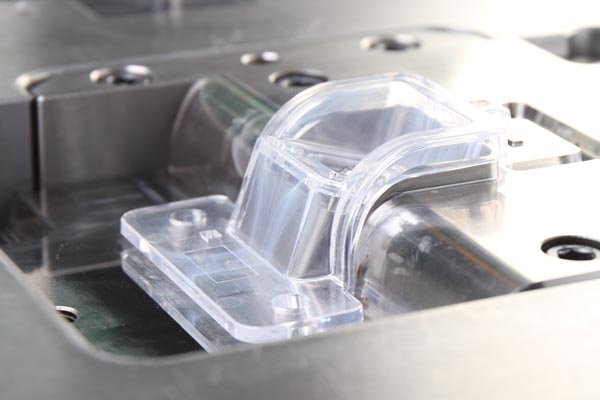

Faced with the myriad challenges of traditional methods, Dongguan Yize Mold Co., Ltd. has actively explored innovations and introduced advanced intelligent temperature control technology in mold processing. Before the punch is pressed into the die cavity, the company ingeniously utilizes the cooperation of locating pins and locating holes to precisely position and correct the upper and lower molds. This crucial step ensures accurate guidance of the punch when it is pressed into the die cavity, laying a solid foundation for high-quality product forming.

More notably, the company is equipped with a real-time detection system capable of accurately monitoring the surface temperatures of the punch and die cavity. Based on the real-time detection data, the temperature control system responds promptly and intelligently controls the water cooling tank to precisely adjust the temperatures of the punch and die cavity. Through this intelligent control method, it effectively prevents mold thermal expansion and deformation caused by excessive temperatures, greatly safeguarding the machining accuracy of injection molds and improving product qualification rates and production efficiency.

If you are troubled by temperature control issues in injection molds, are interested in our intelligent temperature control services, or require any technical support, please feel free to call us at: 13302615729. We are more than willing to share our professional insights in the field of precision injection molds and provide you with cost-effective precision mold injection molding solutions tailored to your needs, working hand in hand to create a new landscape of efficient and high-quality injection molding production.