I. Introduction

In the plastic processing industry, injection molding is a crucial process widely used in the manufacturing of various products. So, what are the unique advantages of two-color injection molding?

II. Basic Concepts

First, this is a more complex process that allows the use of two different colors of plastic materials in a single injection molding process. With this technology, multiple colors can be cleverly combined on one product, greatly enhancing the product’s aesthetics and design freedom.

III. Process Procedures

The process of two-color injection molding is complicated. It requires the injection of two different colors of plastic into different areas of the same mold. For this purpose, a specialized injection molding machine is usually required. This machine is equipped with two independent hoppers and injection systems, which can precisely control the injection volume, speed, and sequence of the two types of plastic. Meanwhile, the injection mold also needs to be specially designed to ensure that the two plastics can fuse perfectly at the correct positions to form the desired product.

IV. Product Characteristics

Products from two-color injection molding have a higher degree of design freedom. By cleverly combining two different colors of plastics, a rich variety of appearance effects can be created, significantly improving the product’s attractiveness. In addition, it can also meet some special functional requirements, such as differences in hardness, wear resistance, and anti-slip properties in different color areas.

V. Application Fields

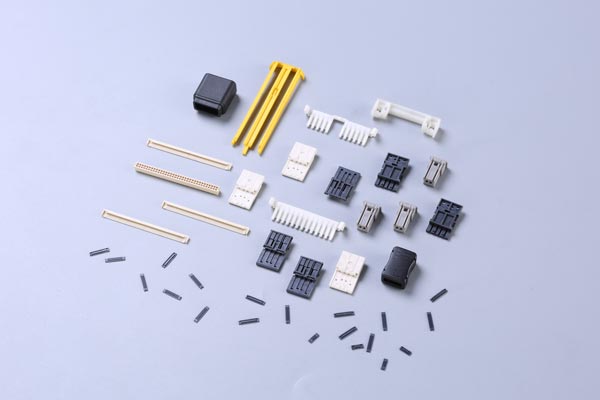

Two-color injection molding is more commonly applied in fields with high requirements for product appearance and design, such as toys, stationery, and electronic products.

VI. Conclusion

There are obvious unique advantages of two-color injection molding in terms of process procedures, product characteristics, and application fields. And it enhances the aesthetics and design freedom of products by using two different colors of plastic materials in a single injection molding process, making it suitable for fields with high requirements for product appearance and design.

In practical applications, it is necessary to select the appropriate injection molding process according to the specific needs and design requirements of the product. At the same time, with the progress of technology and the increasing importance consumers place on product appearance design, this technology will play a more important role in the future.