In the context of rapid technological evolution in manufacturing, plastic injection molding has emerged as a cornerstone for mass-producing plastic components with unparalleled efficiency, flexibility, and sustainability. Despite challenges such as high initial mold costs and design complexity constraints, its long-term benefits far outweigh short-term investments. This article systematically analyzes how plastic injection molding delivers sustainable competitive advantages across four key dimensions: cost optimization, production efficiency, material adaptability, and environmental value.

1. Cost Optimization: Automation-Driven Economies of Scale

Plastic injection molding achieves significant cost reductions through highly automated production lines, enabling large-scale manufacturing at minimal unit costs. Automated systems operate continuously with minimal human intervention, slashing labor costs from over 30% in traditional methods to below 10%. For instance, an automotive interior component manufacturer utilizing a single injection molding line can produce over 1 million parts annually, reducing per-unit costs by 65% after amortizing mold expenses. Precision process control further minimizes defect rates to under 1%, saving on raw material waste and rework costs, ultimately delivering more competitively priced end products to customers.

2. Efficiency Revolution: Dual Advantages of High Precision and Speed

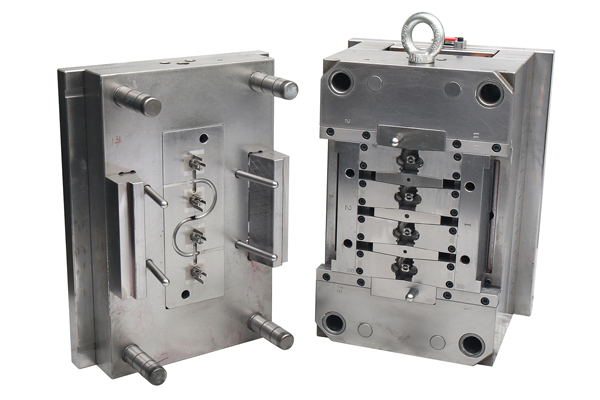

The technology ensures rapid molding of plastics into desired shapes within 3–60 seconds per cycle through high-pressure injection and accelerated cooling systems, cutting cycle times by 80% compared to conventional compression molding. Integrated CAD/CAE simulation tools optimize runner layouts and cooling channels in advance, boosting production efficiency to over 95%. A medical device manufacturer, for example, adopted a multi-cavity mold design to simultaneously produce 16 precision catheter connectors per injection, increasing daily output from 2,000 to 50,000 units while meeting stringent quality and consistency standards.

3. Material Compatibility: From Commodity Plastics to High-Performance Engineering Materials

Plastic injection molding supports a broad range of materials, including general-purpose plastics (PP, PE, ABS) and engineering-grade polymers (PA, POM, LCP), as well as glass fiber-reinforced (GFRP) or carbon fiber-reinforced (CFRP) composites. This versatility allows manufacturers to tailor material selection to product performance requirements: flame-retardant PC/ABS for electronic connectors, weather-resistant ASA for outdoor furniture, and high-strength PEEK for aerospace components. Crucially, sprue and runner waste can be ground and reused at 10%–30% ratios, combined with closed-loop recycling systems, achieving over 90% material utilization rates and significantly reducing resource consumption.

4. Green Manufacturing: Pioneering Circular Economy Models

Compared to traditional cutting or thermoforming processes, injection molding minimizes material waste through precise shot size control, reducing raw material losses to under 0.5% with centralized feeding systems and intelligent weighing modules. A leading home appliance company leveraged an AI-driven process optimization platform to cut energy consumption by 18% while adopting waste regeneration technology to eliminate 1,200 tons of plastic waste annually. Compatibility with bio-based plastics (e.g., PLA, PHA) and biodegradable materials (e.g., PBS) further positions injection molding as a catalyst for transitioning the plastics industry toward circular economy principles.

Conclusion

Plastic injection molding redefines modern manufacturing standards by integrating cost efficiency, production agility, material innovation, and environmental stewardship. Its applications span consumer electronics, medical devices, automotive engineering, and renewable energy sectors, with boundaries continuously expanding. As digital twin technology and industrial IoT converge, injection molding is evolving into an intelligent, flexible, and sustainable production paradigm, driving high-quality development across global manufacturing ecosystems.